Manufacturing companies are adopting computer vision to address specific challenges in quality control, inspection, and production efficiency. Instead of relying on manual checks, many teams now use automated visual systems that work continuously and without fatigue. Computer vision in manufacturing allows real-time monitoring of defects, equipment, and assembly lines. As error rates decrease, production speed and consistency improve.

Modern industrial settings demand more than just traditional automation. Image-based AI systems identify surface flaws, detect missing parts, and track processes with precision. With the proper setup, a factory can run inspection processes at higher speeds while maintaining full traceability.

To achieve this, companies often turn to computer vision development services. These services cover the full scope: from hardware selection and dataset collection to software integration and deployment. Without experienced support, it becomes difficult to scale systems or maintain reliability across multiple product lines.

The goal of using computer vision is not to replace people but to improve accuracy where human inspection falls short. When implemented correctly, it becomes a long-term technical asset that supports leaner and more consistent operations.

Understanding the Role of Computer Vision in the Manufacturing Industry

Using AI & computer vision solutions in manufacturing allows you to solve measurable issues, like visual inspection errors, downtime, and process delays, without replacing skilled labor. You can apply visual AI systems directly on the line to track assembly accuracy, detect anomalies, or check the surface quality of each item.

Computer vision systems do not tire, and when calibrated well, they avoid subjective judgments common in manual checks. Instead of investing in full-scale robotics, many companies choose to upgrade visual inspection first. You get faster return, better integration with existing processes, and access to valuable data points.

What Is Computer Vision and Why Does It Matter in Manufacturing

Computer vision uses cameras and AI models to recognize patterns, classify objects, and detect flaws. In manufacturing, it becomes part of the workflow, checking alignment, measuring tolerance, or validating part presence without slowing down production. You don’t need massive infrastructure changes. Often, cameras and edge devices are installed directly above conveyor lines or workstations.

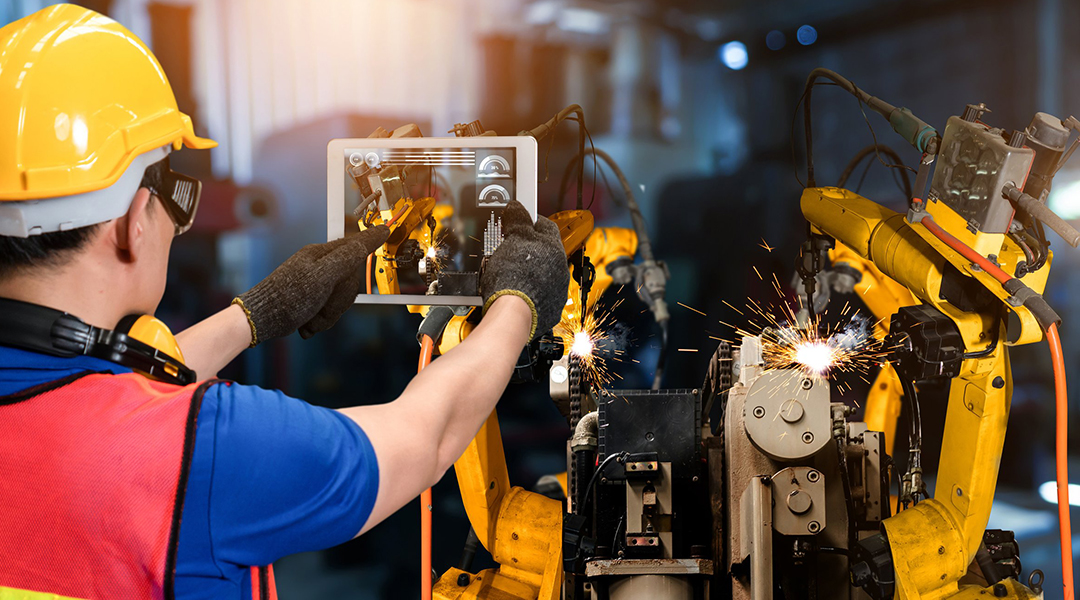

Using augmented reality in manufacturing is another step. For instance, when a technician wears AR glasses powered by computer vision, the system can highlight missing bolts, detect misplacement, or provide live instructions. Maintenance crews benefit from hands-free, guided diagnostics. Assembly workers receive alerts if a part doesn’t match the CAD reference.

You apply computer vision where consistency, speed, and visual clarity matter more than touch or weight. By minimizing manual errors, you reduce scrap and rework while staying in control of traceability.

The Shift from Manual Inspection to Automated Vision Systems

Manual inspection often fails to scale. You can't guarantee that each worker checks parts with the same focus during long shifts. Lighting, fatigue, and even posture affect how humans assess quality. Computer vision systems remove that variability.

A practical shift happens when you deploy a vision solution alongside your human inspectors and compare outputs. In many factories, automated systems outperform staff in speed and repeatability. Once your engineers validate that the AI consistently catches the same defects as the top inspectors, you move toward full adoption.

Different types of systems exist:

- 2D systems. Used for surface-level checks like scratch detection or printed label verification.

- 3D systems. Measure shape, depth, and dimension—ideal for molded parts or complex assemblies.

- Thermal and multispectral systems. Identify material inconsistencies not visible to the naked eye.

You can start small with one workstation or product line. Over time, as confidence grows, the same systems scale across shifts and locations.

Cost, Speed, and Precision: The Benefits of Computer Vision

A well-integrated computer vision setup improves production metrics fast. Precision becomes consistent, and decision-making shifts from guesswork to data.

Essential benefits include:

- Lower error rates. Fewer false positives and missed defects mean reduced scrap and customer complaints.

- Faster inspection cycles. Cameras process hundreds of units per minute without pause.

- Cost savings over time. You avoid costly recalls or warranty claims by identifying defects early.

- More usable data. Vision systems log each inspection, giving you traceability without extra paperwork.

Startups and global manufacturers alike use vision AI to check weld quality, solder joint accuracy, or product labeling. Even small errors, like a rotated sticker, get flagged in milliseconds. Instead of relying on post-production checks, you can catch problems upstream and cut rework. Small steps toward automation, starting with visual QA, often deliver the highest ROI across your entire digital transition.

What Business Owners Should Know Before Starting Computer Vision Projects

Before starting any computer vision initiative, define the exact problem you want to solve. You don’t need to build complex infrastructure to get value. Many manufacturers start with one use case, such as detecting missing parts or verifying product orientation. Focus on a setup that fits your existing workflow. Skipping the planning phase usually leads to poor data quality, mismatched hardware, or misaligned goals. Treat your first vision project like a production tool, not a tech experiment.

Defining Clear Objectives for a Computer Vision Solution

To use computer vision effectively, link your goals to a specific production outcome. It might be reducing false rejects on a line or replacing manual label verification. Without a measurable target, your project becomes a sunk cost.

Start by identifying the exact pain point. Is it the visual inspection of weld seams, counting parts on a tray, or checking fill levels in packaging? Then assign a metric. For example, reduce human error by 30% within three months or increase inspection throughput by 40 units per minute.

Digital transformation in manufacturing only works when each new system addresses a real bottleneck. Avoid vague ideas like "improving automation." Instead, define what your factory needs and how a camera-based system can support that outcome.

When everyone on your team understands the scope, from operators to engineers, integration becomes faster. Your goal is not to automate everything at once. Your goal is to make one step of your process more reliable through consistent visual feedback.

Choosing the Right Hardware: Cameras, Sensors, and More

Not all camera systems work for all tasks. For example, inspecting transparent materials requires different optics than tracking assembly sequences. Selecting hardware without understanding your use case leads to slow, inaccurate systems.

Start with a simple question: what does your vision system need to see? Surface scratches, color changes, part alignment, and shape detection each require a specific type of sensor and resolution. Use monochrome cameras for high-speed contrast detection, RGB for color-based checks, and 3D cameras for volume and shape measurement.

Sensor positioning is just as critical. Poor lighting and unstable mounts will affect accuracy. Test camera angles directly on your line before locking in hardware purchases.

Some components to consider are:

- Lens type. Affects clarity, depth of field, and focus.

- Sensor resolution. Must match the smallest defect or feature you need to detect.

- Processing unit. Choose between edge devices or cloud-based models depending on speed and latency needs.

Careful planning up front prevents expensive redesigns later in the project.

Data Strategy: Collection, Annotation, and Storage

Without high-quality data, no computer vision model will work properly. Training AI requires thousands of labeled examples of both correct and incorrect parts. Collecting blurry or inconsistent footage wastes time and produces weak models.

Begin by recording production video or capturing high-resolution photos of every variant in your process. Include defective items that match your failure modes. Then, use annotation tools to mark the features you care about, such as scratches, gaps, misalignments, and incorrect colors.

Avoid outsourcing annotation blindly. Your engineers understand your defects better than external data teams. Review annotated datasets closely to make sure they reflect the real production standards.

A couple of actions to take may include:

- Standardize lighting. Lighting affects model accuracy as much as camera choice.

- Organize images. Group by defect type, part type, or production stage.

- Define storage rules. Keep labeled data in secure, searchable formats, ideally with timestamps and part IDs.

Good data makes future retraining easier and improves system accuracy over time.

Book a call with our professionals to learn what computer vision solutions.

Comparing Popular Computer Vision Software for Manufacturing Industry Use

When selecting software for visual inspection or process control, avoid general-purpose tools that lack real-time performance or industrial integration options. You can work with vendors offering manufacturing software development services or explore pre-built libraries and platforms. Each route depends on the specificity of your inspection task, the required cycle time, and the level of flexibility needed. Always compare tools based on speed, integration ability, and long-term support, not just demo performance.

OpenCV vs. Industrial Suites — Main Differences

OpenCV is widely used because it’s free, well-documented, and flexible. You can build highly customized systems from scratch if you have a skilled internal team. However, OpenCV lacks ready-made interfaces for industrial protocols like OPC UA or real-time PLC integration.

Industrial suites such as Cognex VisionPro or Matrox Imaging Library come with built-in I/O, lighting control, and hardware calibration tools. They also include certified support, training, and version stability, which helps when deploying across multiple sites.

| Feature | OpenCV | Industrial Suites (e.g., Cognex, Matrox) |

| Cost | Free, open-source | Licensed, often subscription-based |

| Customization | High flexibility, full code access | Limited customization, designed for specific use cases |

| Ease of Integration | Requires manual coding for I/O and PLC support | Built-in support for factory systems and protocols |

| Deployment Time | Longer due to development and testing needs | Faster with pre-built tools and templates |

| Support and Documentation | Community-based, varies by topic | Vendor-provided support, structured documentation |

| Best Use Case | R&D projects, academic, fully custom systems | High-speed, stable, factory-grade visual inspections |

Use OpenCV when building tailored systems in-house. Choose industrial suites when production speed, uptime, and integration with existing infrastructure are essential.

Features to Look for in Production-Ready Software

You need more than object detection. Software must connect directly to line controls, store image logs, and allow real-time decision-making with no delay. Visual tools alone don’t qualify a platform as production-ready.

Look for these features:

- Edge processing capability. Reduces latency and avoids cloud dependency.

- PLC integration. Allows real-time rejection, labeling, or sorting actions.

- Auto-retraining functions. Updates models based on new image sets over time.

- Alert and reporting tools. Must generate reports per shift, per defect, or per part number.

- Version control. Tracks updates and changes across inspection rules or software configurations.

If your inspection speed is measured in parts per second, you need software that supports threaded operations, GPU acceleration, and batch control logic.

Licensing, Support, and Scalability Considerations

One-time licenses often seem cheaper but come without long-term technical help. Subscription models add cost but usually include support, bug fixes, and update cycles.

Before committing, check how the vendor handles deployment at scale. Will your license cover five production lines or just one? Is there an extra cost for adding more cameras or users?

Important factors to evaluate:

- License scope. Per device, per camera, or per facility.

- Support availability. Response time during production hours.

- Upgrade policy. Whether updates break existing workflows or stay backward-compatible.

- API access. Needed for custom integration with MES or ERP systems.

Choose software based not only on today’s project but also on what your factory might need next year. Flexible license terms and clear upgrade paths help avoid future rebuilds.

Top Computer Vision Applications in the Manufacturing Industry

AI-based vision systems transform tasks that involve visual checks into scalable, automated steps. Examples include welding inspections in the automotive industry, PCB testing in electronics, and food safety checks in processing plants. Each use case demonstrates how camera-driven tools accelerate inspection, minimize errors, and deliver clear production metrics.

Automotive: Spot Welding Defect Detection with Deep Learning

Spot welding holds frame components together. Deep learning models now inspect hundreds of weld points per second.

Faster R‑CNN models trained on body‑in‑white images reached over 90 % accuracy at 15 fps using high-confidence anchor boxes and VGG‑16 feature extractors. Another study used YOLO‑Weld with transfer learning to locate laser weld points in real production settings.

Workflow usually looks like this: train on labeled good/bad weld samples, test on a live line, then match model output with physical part IDs. When done right, you avoid costly rework or part failures due to missed weld faults.

Electronics: PCB Inspection Using Vision Algorithms

Printed circuit boards contain tiny traces, holes, and solder joints. Manual inspection struggles at high volumes. University research shows PCB inspection systems using template subtraction and threshold checks reliably flag missing components and misaligned parts. Engineers at Maryland described a smart machine vision system that spots solder paste defects on PCBs using machine learning methods.

Modern vision setups combine 2D optical cameras with AOI tools and sometimes X‑ray systems to detect hidden faults. Processing time falls to milliseconds per board with accuracy matching or exceeding trained inspectors.

Food Processing: Contamination and Packaging Error Reduction

Food plants handle fragile and perishable items. Vision AI helps maintain safety and compliance. Oregon State University researchers combine optical sensors, robotics, and ML to inspect fruit, measure color and texture, and spot chemical contamination without halting the line. Another study links vision systems to upstream process control in packaging, spotting improper seals or foreign objects using X‑ray and hyperspectral scanning.

Tyson Foods tested vision systems to monitor hygiene steps and detect foreign items in production lines. Similar tools improve safety compliance and reduce recalls, offering direct reports for quality control teams.

Discover how vision-driven AI and computer vision deliver real-time quality control, automation, and performance insights across industries. Read the white paper to explore practical frameworks and high-impact use cases built for measurable results.

Building a Scalable Computer Vision Solution for Manufacturing

Scaling computer vision means more than adding more cameras or servers. You need a solution that continues to work effectively as product types, defect categories, or production speeds change. Most manufacturers begin with one use case and then expand based on real-world performance data.

Successful scaling depends on stable integration, trained teams, clear objectives, and continuous data updates. Instead of running isolated projects, build a system that fits your workflows and can evolve alongside process changes or quality demands.

Working with AI Integration Partners or Internal Teams

For computer vision quality control to work under real conditions, you need both strong software and correct deployment. You can build internally or bring in an AI integration partner, depending on your team’s experience and speed goals.

Internal teams know your process best. However, they often lack expertise in training computer vision models, tuning camera parameters, or maintaining pipelines. Partners bring that experience but require close collaboration to meet plant-specific needs.

Pros of internal development:

Better process insight. Engineers understand tolerances and reject limits.

Faster iteration cycles. Immediate access to production environments.

Pros of working with partners:

Pretrained models. Faster baseline accuracy from day one.

Hardware-software alignment. Expertise in sensor placement and edge optimization.

For high-yield lines, combine both: internal engineers manage quality logic while outside teams configure models and infrastructure. That structure supports stable and repeatable quality control at scale.

From PoC to Full Deployment: Phases of Implementation

A proof of concept (PoC) helps verify if computer vision for learning defect patterns or tracking parts are viable in your environment. Many companies stop after PoC without progressing to full-scale rollout. That’s usually due to unclear goals or poor planning.

The phases to follow:

- Data validation. Capture labeled images of good and bad units, covering real production variety.

- PoC test. Run the model on a small batch or an offline camera to confirm detection quality.

- Pilot stage. Integrate with one line or station, track missed defects and false positives.

- Rollout. Expand to other lines after hitting the target accuracy for at least one full shift.

Computer vision for learning depends heavily on iteration. Feedback from operators improves training data. Production logs improve retraining cycles. Avoid skipping pilot validation; each station brings unique challenges, even if the product stays the same.

KPIs for Measuring Success in Vision-Driven Automation

Measuring success in visual AI systems requires clear, actionable metrics. Inspection speed or accuracy alone isn’t enough if the system causes more false rejects or overloads your support staff.

Trackable KPIs are:

- Defect detection rate. Percentage of true positives on known defect types.

- False reject rate. Number of acceptable parts wrongly marked as defective.

- Inspection cycle time. Average time per image or part.

- Uptime. The time system operates without intervention.

- Cost per inspected unit. Total cost divided by units checked.

Review KPIs monthly to adjust models or processes based on real factory performance.

Common Computer Vision Applications in Manufacturing

Computer vision systems are now applied across multiple steps in the production line. Manufacturers use them not just to catch defects but to monitor processes, verify labeling, and enhance safety in real time. Applications span from simple barcode checks to complex inspection of micro-defects or incorrect assembly steps. The main value comes from removing guesswork and introducing consistent, automated visual confirmation where errors are likely to happen.

Real-Time Defect Detection in High-Speed Environments

In high-throughput production, you need inspection systems that react in milliseconds. Computer vision models trained on surface imperfections, shape deviations, or missing components can detect failures as products move past a camera at full speed. The advantage is consistency. Once trained, the system evaluates each part under identical conditions, with no fatigue or variation. Real-world use includes bottle cap sealing checks, weld inspection in automotive, or chip placement in electronics. Instead of slowing lines for manual review, vision tools offer reliable feedback without bottlenecks.

Assembly Line Monitoring and Worker Safety Tracking

Computer vision setups on assembly lines now monitor process steps and worker behavior simultaneously. If a tool is missing from a station or a worker skips a step, the system records the deviation instantly. In safety-focused workflows, cameras identify when protective equipment is not used or when zones are breached.

Unlike legacy sensors, vision tools observe patterns in motion and context. That means faster detection of unusual situations without requiring new physical infrastructure. You get detailed logs and alerts, helping both production managers and safety officers respond with precision.

Barcode, OCR, and Label Verification Use Cases

Before products leave the factory, their labeling must be correct. Computer vision reads barcodes, serial numbers, expiration dates, and regulatory symbols using OCR and pattern matching. Misprints, misalignments, or wrong codes can trigger line alerts.

Unlike handheld scanners, these systems run automatically and continuously, matching labels with internal databases or production orders. Whether it's pharmaceutical batch numbers or food packaging labels, even small errors are caught early. Reliable verification avoids shipment issues, recall risk, or legal violations in tightly regulated industries.

Inventory Management and Part Recognition

Computer vision helps automate inventory tracking by visually identifying parts, materials, or packaging without barcodes or manual input. Cameras placed above shelves, bins, or conveyors recognize item shape, color, or dimensions and match them to a digital record.

In assembly environments, the system can confirm the presence of correct parts before production begins, reducing rework. For warehouse operations, vision tools count items as they move in or out, updating inventory databases in real time. You avoid delays caused by scanning errors or human oversight.

The Prospects of Computer Vision Applications in Manufacturing

Computer vision will continue expanding as factories move toward fully connected systems. Integration with digital twin in manufacturing allows real-time tracking of parts and processes, linking visual input with virtual models for accurate analysis and forecasting. As visual AI tools become faster and more adaptable, they will support predictive decisions, reduce manual oversight, and help align performance across different sites. Future use cases will focus not only on quality but also on process learning, simulation, and optimization.

Predictive Maintenance Using Vision + AI Models

Instead of reacting to equipment failures, manufacturers use cameras to track wear indicators, surface changes, or performance shifts before breakdowns occur. Vision models trained on historical images can spot early signs of misalignment, overheating, or contamination. Operators get alerts before any damage affects output.

Systems can monitor conveyor belts, robotic arms, or cutting tools without interrupting operations. Once deployed, the camera feeds continuously into AI models that improve with time, providing increasingly accurate warnings and maintenance timelines.

Cross-Factory Standardization Through Vision APIs

Factories that operate in different regions often struggle to maintain consistent inspection standards. Vision APIs allow centralized logic to run across multiple plants by using the same model version, configuration, and detection rules. Instead of retraining each system locally, updates can be deployed remotely.

The uniformity helps global teams detect defects in the same way, share performance metrics, and audit systems more effectively. Standardization also facilitates easier comparison of output quality across sites and reduces training time for new operators.

The Role of Synthetic Data and Simulation

Collecting enough defect images for training can be slow or impractical, especially for rare failure modes. Synthetic data generation creates labeled samples using 3D models, controlled lighting conditions, and software-generated anomalies. Vision systems trained on these synthetic datasets can recognize issues they’ve never seen in real life. Simulation tools also test inspection models in virtual environments before hardware is installed.

Critical Challenges of Computer Vision in Manufacturing

Manufacturers face several recurring challenges when implementing computer vision systems. Inconsistent defect detection often results from manual inspection, where outcomes vary based on fatigue or lighting. Many teams lack the internal expertise to manage tasks like data annotation, model training, or optimal hardware setup.

- Inconsistent defect detection. Manual inspection leads to variable results due to fatigue, lighting conditions, and subjective judgment.

- Lack of in-house expertise. Many teams lack the skills needed for data labeling, model training, or hardware setup.

- Scalability issues. A system that works in one factory often performs poorly when applied to a different line or product type.

- High false reject or accept rates. Vision models may incorrectly classify parts, either causing unnecessary scrap or allowing defective items through.

- Insufficient real-time processing. Delays in visual data handling can interfere with high-speed production environments.

- Weak system integration. Vision solutions often do not connect well with MES, ERP, or PLC systems already in use.

- Disruption during implementation. Deploying new hardware or models can force production downtime and reduce throughput temporarily.

Program-Ace helps manufacturers handle these challenges through fully integrated solutions. We support you at every stage, from defining your goals to deploying stable, scalable computer vision systems tailored to your operations.

How Experts at Program-Ace Can Enhance Your Computer Vision in Manufacturing

Program-Ace acts as an innovative solutions integrator, helping manufacturers move from concept to deployment with tailored computer vision systems that work on the production floor. We focus on solving specific challenges, such as defect detection, real-time inspection, or inventory tracking, by combining AI models, custom software, and reliable hardware setups.

Whether you need to integrate vision tools with existing PLC systems or scale your solution across factories, our team builds systems that fit your process rather than forcing a one-size-fits-all model. You get direct access to experts in computer vision, machine learning, and industrial systems who work with you to define goals, develop a plan, and deliver working results that stand up to daily use.

Contact us to discuss your production goals and receive support from a team that understands the unique conditions within manufacturing environments.