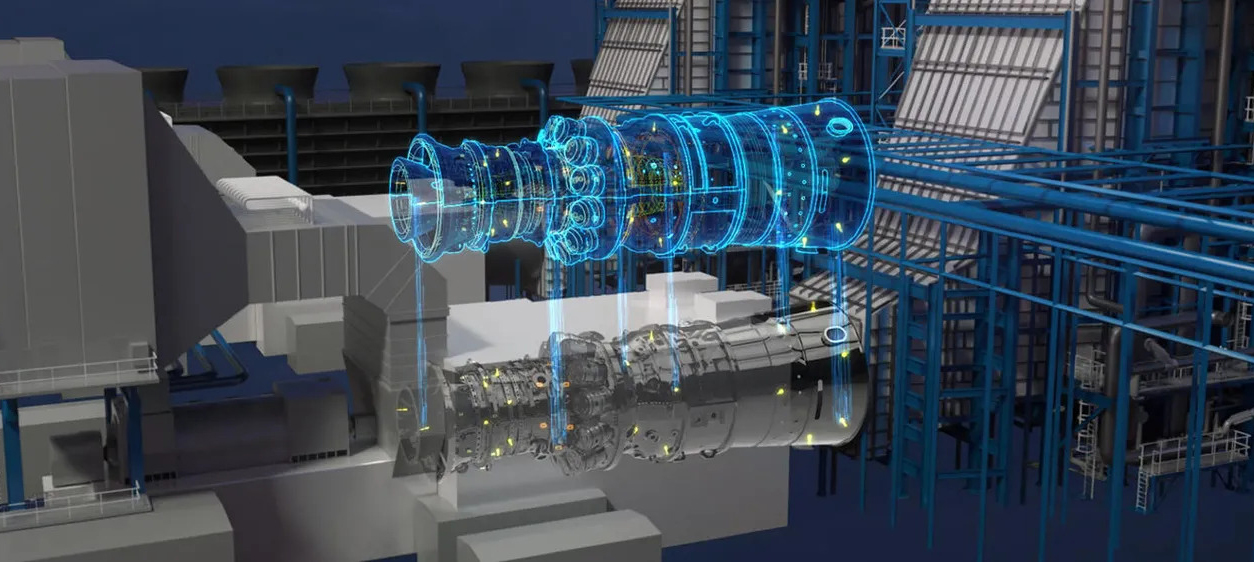

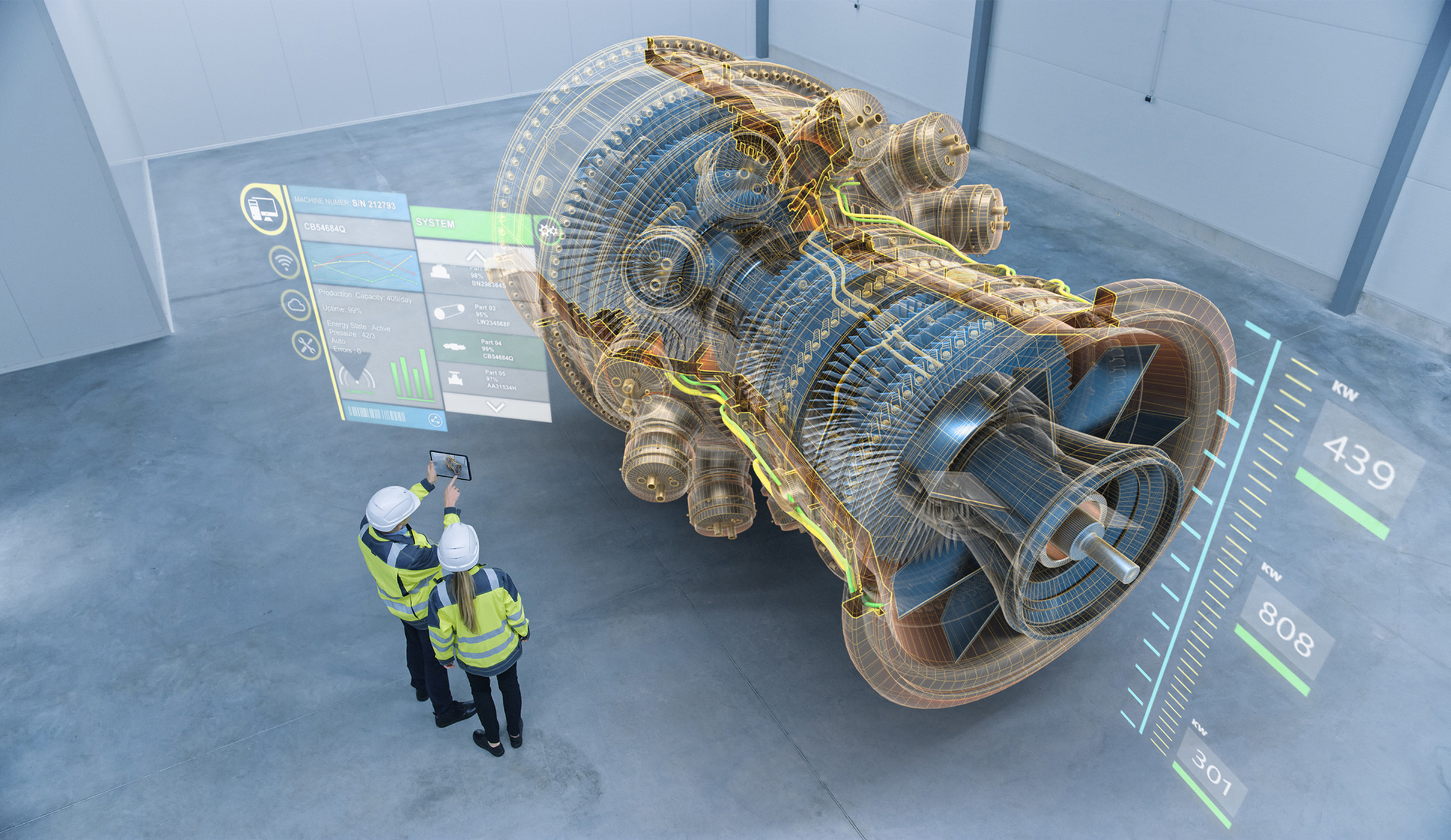

Manufacturers want clear ways to cut R&D costs without slowing development, and many teams already see how digital twins solutions supported by AI provide that kind of control. Our specialists work with companies that struggle with long prototype cycles, high material waste, and engineering decisions that depend on incomplete data. AI-powered digital twins remove those gaps through accurate virtual prototypes that react to real inputs, real constraints, and real system behavior.

You gain a model that updates as your engineers test ideas, adjust parameters, or add new requirements. Your organization avoids repeated physical builds when a digital version predicts failure points, performance limits, and improvement options early in the cycle. R&D teams use the same environment to compare variations, confirm feasibility, and validate design choices with fewer surprises later.

The approach shortens verification time, cuts experiment costs, and supports cleaner handoff to production. Our experts help companies tie AI models to sensor data, simulation tools, and engineering workflows so that every prototype stage becomes measurable and predictable. Manufacturers using AI-supported digital twins report faster development, fewer redesign rounds, and a more stable understanding of product behavior before any physical object is built.

Why Digital Twin AI Is Transforming R&D Efficiency

Manufacturers look for direct ways to cut R&D overhead without reducing prototype quality, and AI-supported digital twins now provide that path. Teams gain a virtual environment that reacts to real parameters, records every adjustment, and exposes weak points long before hardware reaches the floor.

Our specialists often link models to production data so engineers can test more ideas at a lower cost. Many companies request artificial intelligence development services for this purpose, since integrating AI into digital twins allows faster scenario evaluation and cleaner decision cycles. R&D workflows become more predictable once each prototype iteration runs through a controlled simulation.

How AI Digital Twins Reduce Iteration Cycles in Early-Stage Prototyping

R&D teams can spend weeks adjusting early prototypes that fail for avoidable reasons, and many of those delays disappear once AI-driven simulation models run alongside design work. A digital twin reacts instantly when an engineer changes load expectations, geometry, or material behavior.

Prototypes mature faster because every adjustment is validated before physical production starts. Companies using manufacturing software development services often request deeper automation in this stage, and AI models provide it without adding complexity to engineering tasks.

Many teams ask how AI actually changes the early prototyping stage, so the contrast below shows the difference in a simple, direct way:

| Stage | Without AI Twin | With AI Twin |

| Early feasibility checks | Manual tests, slow insights | Immediate system responses |

| Material choice validation | Multiple physical samples | Virtual stress and durability tests |

| Iteration count | High and unpredictable | Lower and more stable |

Three direct effects appear most often in our projects:

- Faster adjustments. Engineers refine geometry or logic without waiting for new hardware.

- Cleaner visibility. AI highlights patterns that show where a design underperforms.

- Lower material waste. Fewer physical builds reduce unnecessary spending.

Why Combining Digital Twin and AI Enhances Decision Accuracy in R&D

Strong decisions in R&D depend on complete data, accurate predictions, and a stable view of system behavior. AI-supported digital twins provide all three through continuous model updates that reflect real constraints. Teams understand how a prototype behaves under load, temperature, vibration, or extended use because the simulation environment mirrors real production conditions.

Many organizations pursuing digital transformation in manufacturing rely on this combined approach to remove uncertainty from design reviews, long-term planning, and component validation.

A simple bullet list works well here because the advantages fall into clear categories:

- Unified data. Digital twins draw on sensor data, design files, and test records.

- Early clarity. AI spots conflict points in geometry, timing, or logic.

- Predictable planning. Engineers review accurate performance trends before approving builds.

- Confident approvals. Teams rely on validated results rather than assumptions.

A structured workflow usually emerges after adoption. Engineers feed parameters into the model, AI evaluates likely outcomes, and the twin updates behavior instantly. Costly trial-and-error cycles fade, and decision-makers gain trustworthy evidence before committing resources. R&D budgets benefit because measurable results back each decision.

The Core R&D Problems AI and Digital Twins Actually Solve

R&D teams often waste time dealing with unclear performance data, incomplete failure insights, and prototype versions that fail for avoidable reasons. AI-enhanced digital twins address these issues by providing engineers with a stable model that shows how a design behaves under real constraints.

You avoid long testing cycles by gaining clear indicators of stress, temperature impacts, vibration effects, and other factors before creating anything physical. Our team sees consistent improvements in decision speed, design clarity, and coordination between engineering groups once digital twins become the first step rather than a side tool.

Eliminating Expensive Physical Prototypes Through Precise Virtual Modeling

A large share of R&D cost overruns comes from repeated physical builds that don't bring teams closer to a usable design. AI-assisted virtual modeling solves that problem by mirroring material behavior, geometry, and operational loads with far more accuracy than earlier simulation tools.

Engineers adjust a parameter and see the digital model respond right away, so progress never stalls while waiting for new parts. Digital twin in manufacturing often becomes the central reference point because it captures every change, from shape refinement to load redistribution.

The shift is easy to feel once the first project cycle runs through a virtual twin. Teams stop guessing how many physical prototypes they need because the model handles most exploration. Hardware becomes a verification step rather than a trial-and-error tool.

Many organizations note that early confidence grows once the virtual version reveals weak points before money is spent on machining, shipping, or assembly. R&D leads gain a more straightforward planning path, and engineers spend more time improving the design rather than reacting to late discoveries.

Predicting Failures Before Build Phase With AI-Driven Simulation

Unexpected failures often occur after parts reach the test lab, and each one triggers delays, redesign work, and increased costs. AI-driven simulation reduces that cycle by showing where a design may fail long before anything moves to production. Engineers view stress concentrations, dynamic loads, deformation points, and long-term fatigue estimates inside a controlled digital environment. No table is needed here because the flow is easy to explain in plain language.

An engineer sets up the conditions, adds relevant forces, and selects the expected operational scenario. The AI engine studies the model, flags areas that fall outside acceptable ranges, and suggests where changes might reduce risk. R&D teams learn which shapes or materials hold up under stress and which ones need revision. Many organizations report fewer late-stage surprises because most structural or thermal problems surface early when corrections are faster and cheaper.

Early detection supports a calmer, more predictable R&D process. Decisions rely on documented simulation outcomes, not assumptions or rushed testing rounds. Once failure risks shrink, engineering teams move toward production with higher confidence and tighter control over resources.

How AI Digital Twins Create Smarter Virtual Prototyping Pipelines

Many R&D pipelines slow down because early evaluations depend too heavily on physical testing. AI-supported digital twins shift that balance by turning prototype work into a data-driven sequence where every update is checked inside a controlled simulation space.

More teams now model systems in the same way major firms use digital twins in construction, meaning the prototype evolves as conditions change rather than staying fixed. Engineering groups gain a clearer progression from concept to validation because the twin records every input, runs faster simulations, and exposes design limits long before hardware enters the workflow.

Integrating Real Factory Data into Digital Twin AI Models for Continuous Refinement

Stable virtual prototypes depend on accurate data, so real factory inputs often become the core driver behind AI-enhanced twins. Machine signals, sensor readings, material behavior, and environmental conditions all strengthen the model over time. The goal isn't piling on data, but shaping a system that reflects how equipment behaves across shifts, loads, and operating states. A quick example: a team experimenting with early robotics layouts uses conveyor speed logs and actuator temperature traces to refine movement patterns inside the twin. Patterns become clearer, and variation from shift to shift stops being a guessing game.

The shift becomes clearer when viewed in a small side-by-side layout:

| Data source | Refinement effect |

| Sensor streams | More accurate system response under changing loads |

| Operator adjustments | Better reflection of practical usage conditions |

One more detail often surprises newcomers. Teams exploring how to create an AI chatbot sometimes notice parallels, because both systems depend on continuous feedback loops; the difference is that a digital twin uses physical data rather than user text. Once the model stabilizes, engineering groups trust it as a living representation of factory behavior, not just a simulation file.

Running Multiple Prototype Scenarios Without Pausing Existing Operations

Production rarely tolerates downtime, so many organizations value digital twins for their ability to test ideas without interrupting ongoing work. A scenario might involve stress changes, geometry shifts, load variations, or long-term fatigue estimates. All of it runs in parallel, leaving the physical line untouched. Engineers swap in new parameters, check the outcome, and move to the next case within minutes.

The speed of the workflow becomes clear once the actions start unfolding:

- Set conditions. Load limits, materials, or geometries change with each subsequent experiment.

- Run simulations. The AI engine evaluates performance across a wide range of outcomes.

- Review contrasts. Strong and weak directions appear side by side.

No single structure fits every project, but scenario libraries grow fast once multiple tests run in parallel. A discussion about types of digital twins often comes up during planning: some teams use component-level twins, others use full production-line versions, and advanced groups combine both into unified systems. Regardless of format, the key advantage stays the same: prototype exploration continues at full speed while operations remain completely undisturbed.

Want to cut manufacturing costs? AI-driven digital twins may help.

The Strategic Value of Using Digital Twin and AI for Cost Reduction

R&D budgets often expand because teams discover issues too late or run more tests than a design truly requires. Digital twins powered by AI reduce that load by predicting behavior early and eliminating many of the blind spots that once required extra prototypes.

Engineers rely on the virtual environment to verify geometry, loads, and operating limits long before physical construction begins. The cost shift is noticeable because fewer materials are consumed, testing windows shrink, and design choices reach clarity sooner. Organizations also gain cleaner traceability, as every adjustment remains documented inside the twin.

Lowering Testing Overhead Through Automated Scenario Generation

Running large sets of tests usually demands significant time and coordination, especially when engineers must prepare conditions manually. AI-driven digital twins ease that burden by generating a wide set of scenarios without requiring extensive prep work.

A design can pass through thermal stress, long-term fatigue, or unexpected load combinations in minutes instead of days. Engineers see what direction to follow sooner because the entire spread of outcomes appears early in the cycle, not after multiple rounds of physical evaluation.

Many projects reveal the same pattern once automated scenarios start running, and a few points tend to matter most:

- Automatic variation. Parameters shift across ranges that would take a long time to configure manually.

- Realistic combinations. AI identifies patterns in past outcomes and blends them into useful test cases.

- Focused review. Engineers spend more time analyzing promising paths rather than setting up each test.

Testing overhead drops because the twin covers dozens of potential situations before the first hardware cut. Many teams report that a single well-configured model eliminates multiple prototype rounds, which directly reduces material use and internal labor hours. Cost control improves naturally once the virtual environment handles most of the exploration.

Faster Validation Cycles Enabled by AI and Digital Twins

Validation usually slows down product development because every adjustment needs confirmation under stable conditions. AI-supported digital twins shorten that wait by providing real-time reactions to design inputs. A change in geometry or load immediately updates the model's behavior, allowing engineers to confirm viability without booking lab space or configuring new equipment. The pace changes dramatically once predictions and measurements flow through the same environment.

No list is needed here because the process is easy to follow in narrative form. An engineer updates a parameter, the twin recalculates system behavior, and the AI layer highlights areas worth a closer look. The entire review loop moves faster because the system retains every version, allowing direct comparisons between earlier and updated designs.

Decision-makers see stronger evidence earlier, reducing the number of approvals required to move forward. Validation becomes a continuous process, not a gate at the end of development. As a result, project timelines contract, and the cost of prolonged testing windows fades along with them.

AI-Powered Simulation Capabilities That Maximize R&D ROI

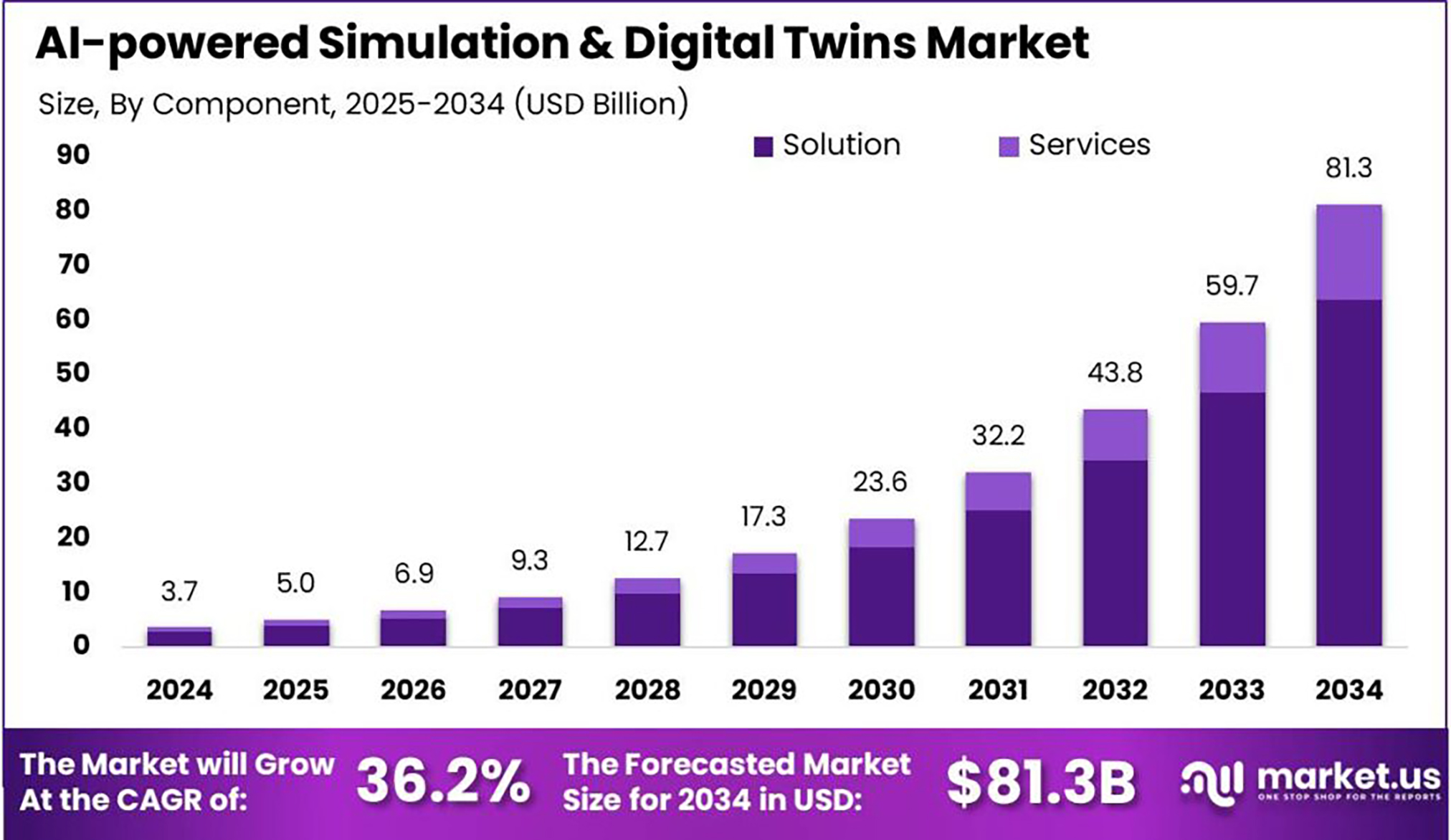

AI-supported simulation changes how R&D teams plan prototype cycles because the model reacts immediately to new parameters and exposes weaknesses long before anything reaches production. Many teams gain an advantage by using scalable visualization platforms such as Cesium development, mainly when prototypes depend on large spatial datasets.

As studies show, only a small share of existing digital-twin systems incorporate real-time data streams, which means the advantage grows quickly once AI-driven simulation finally connects to live inputs. According to Kreuzer et al. (2024), fewer than 3% of reviewed systems operate with real-time data, making AI-enabled simulation one of the clearest opportunities for measurable ROI.

Real-Time Parameter Tuning for Prototype Optimization

Prototype work accelerates when engineers no longer wait for new hardware builds just to test small variations. AI-driven digital twins support that pace because every adjustment, such as geometry, loads, timing, constraints, updates the simulation instantly.

According to the McKinsey analysis of digital twins and generative AI, gen AI can compress and reorganize large operational datasets, allowing real-time tuning to rely on cleaner, more complete inputs instead of scattered logs. Their work also notes that AI can act as an interface layer, helping engineers interpret complex behavior without navigating raw simulation output.

Research highlights an important gap that makes real-time tuning even more valuable. Kreuzer et al. (2024) found that only 2.68% of published AI–digital-twin systems use live data and only 7.38% demonstrate a working feedback loop between the physical and virtual environments.

Once that loop is in place, the pace of refinement shifts noticeably. Designs stabilize earlier, unexpected failures drop, and a large portion of physical iteration becomes unnecessary. Teams reach viable prototypes faster because each change is validated inside the model instead of requiring a full round of setup, machining, and testing.

Multi-Physics and Stress Simulation Powered by Digital Twin AI Models

Multi-physics simulation becomes far more practical once AI sits inside the digital twin. Instead of moving between separate tools for thermal loads, vibration behavior, material deformation, and structural fatigue, engineers work inside one model that handles all of it at once.

A change in geometry, thickness, or load distribution immediately reshapes the outcome, so the weak points show up early. Teams that depend on components with complex interactions often notice how quickly they gain clarity when multiple physics domains respond together instead of in isolation.

Many projects show a similar pattern, where the most valuable gains come from three areas:

- Combined insights. Heat, force, and motion influence each other, so having all effects in one place reduces guesswork.

- Earlier visibility. Stress concentrations appear before fabrication, not after the first prototype fails.

- Direct comparisons. Alternative designs reveal their strengths faster because every version runs through identical multi-physics conditions.

No single workflow fits every industry, yet the shift to integrated simulation usually shortens the time spent on late redesigns. Once the model reacts to real loads across multiple domains, engineers move through decisions with fewer interruptions and reach stable designs earlier in the cycle.

How AI and Digital Twins Improve Collaboration Across R&D Teams

R&D groups rely on fast coordination, yet many delays arise from scattered data and separate interpretations of prototype behavior. AI-supported digital twins change that dynamic by giving teams a shared model that evolves as engineers test ideas and analysts evaluate results.

Conversations become clearer once everyone references the same environment, and feedback flows more smoothly because no one has to wait for updated files or offline reports. As the model tracks every parameter shift, performance trend, and design adjustment, collaboration shifts from individual tools to a single, consistent source of insight.

Maintaining a Single Source of Truth for Engineers and Analysts

Misalignment inside R&D often comes from teams discussing the same design through different datasets or outdated simulations. A digital twin removes that friction by holding every detail, like previous decisions, parameter changes, and recorded outcomes, in one place.

Engineers can focus on how the design behaves under load, while analysts study long-term patterns without wondering whether their inputs match the latest version. The continuity makes a noticeable difference because discussions begin with shared context rather than the usual attempt to reconcile spreadsheets or separate reports.

Once the model becomes the central reference point, the pace of decision-making shifts. Engineers move confidently from one iteration to the next, knowing the history of each change remains intact. Analysts trace outcomes back to the exact conditions that produced them. New members stepping into the project follow the full storyline inside the twin rather than piecing together fragmented documentation. Over time, this consistent view helps projects stay grounded, even as requirements evolve or multiple teams contribute at different stages.

Cross-Department Scenario Reviews Using AI-Enhanced Digital Twin Dashboards

Cross-functional reviews often slow down because each department views the prototype from a different angle. AI-enhanced digital twin dashboards bring those perspectives together by letting teams explore the same scenario as it unfolds. An engineering adjustment might reveal a structural change, which then invites the manufacturing group to evaluate throughput impact, while the product team checks how the shift affects delivery goals. The discussion moves naturally because everyone sees the same reactions in real time instead of interpreting static slides.

Departments draw different conclusions from the same environment, yet the reactions stay connected because they appear in one place:

| Department focus | How the dashboard supports their view |

| Engineering | Clear feedback on load paths and design stability |

| Manufacturing | Immediate understanding of timing, resource use, and process changes |

| Product | Direct visibility into feasibility and trade-offs |

The flow of conversation becomes smoother once every reaction appears within one environment. People stop debating interpretations and start responding to what the model is actually doing. By the end of the review, teams walk away with a shared conclusion instead of parallel notes that must be reconciled later.

Practical Implementation Steps for AI Digital Twins in R&D

Rolling out an AI-supported digital twin works best when teams anchor the effort in practical steps rather than abstract planning. Early projects often rely on tools such as digital twins with Cesium and Unreal Engine, mainly because they handle large environments and complex visual behavior while keeping the workflow responsive. The sequence usually begins with capturing clean data, shaping a model that matches real constraints, and giving engineers a space where changes register instantly. Once the foundation is stable, simulation, analysis, and refinement start feeding into one another, creating a reliable path toward faster prototyping and clearer R&D decisions.

Building the First Data Layer and Choosing the Correct Modeling Approach

Early-stage digital twin work always starts with data, yet the first layer carries more weight than many teams expect. The information shaping that layer (geometry, material behavior, and baseline performance) sets the tone for every later simulation. Once that foundation forms, the modeling approach starts taking shape almost automatically because the data suggests which direction fits the system best.

In practice, teams often reach a point where they need to separate what is essential from what can wait. Several choices tend to guide that moment:

- Depth of modeling. Some situations benefit from detailed physics; others move faster with behavior-based logic.

- Scale of representation. A component-level twin supports precision work, while a system-level model helps evaluate broader interactions.

- Data flow design. Stable inputs anchor the twin; variable or noisy signals must be shaped before they influence the model.

As the structure becomes more coherent, early checks help confirm that the model reacts to changes in a believable way. Engineers test simple interactions, adjust boundaries, and shape the flow between virtual and physical references. Each improvement strengthens the environment, giving later AI-driven features a cleaner base to operate from and helping the twin mature into a dependable R&D tool.

Validating Digital Twin Accuracy Through Controlled Pilot Scenarios

Accuracy grows through repetition, which is why controlled pilot scenarios play such an essential role during the early rollout. Teams start with narrow, manageable tests that reveal whether the virtual system behaves like the physical one. A small shift in load or temperature often says more about model quality than a wide, complex simulation. As pilots unfold, each comparison creates another reference point that helps refine the twin.

Patterns usually start emerging after the first rounds of testing, and specific actions repeatedly help tighten alignment:

- Rechecking assumptions. Baseline inputs occasionally shift once the team sees how the model responds.

- Refining constraints. Boundaries become clearer as pilot results show where the system feels too rigid or too loose.

- Adjusting data quality. Raw signals need filtering or recalibration to determine the twin mirrors' actual behavior.

As the twin absorbs these corrections, the pilot scenarios expand naturally. Engineers compare trends rather than isolated outcomes, analysts observe how well the model holds its shape under varied conditions, and the team gradually gains confidence that the environment reflects real-world behavior. Once the twin reaches that steady state, broader decisions, such as timelines, design direction, and physical tests, stand on firmer ground because the virtual system has already proven itself in controlled conditions.

The Role of Predictive AI in Accelerating Prototype Maturity

Prototype development often slows down when teams need several testing rounds before reaching a stable design. Predictive AI changes that pace by flagging behavior trends early, so engineers understand where a design is heading long before a physical build begins. As the model continues absorbing patterns from prior iterations, its guidance becomes more precise, allowing adjustments to land closer to the final form.

From that point onward, prototype maturity comes faster because each refinement builds directly on the insight generated in the previous cycle. The development rhythm becomes smoother, and many of the delays tied to late-stage surprises begin to disappear.

Identifying High-Risk Design Choices Before Physical Testing

High-risk design decisions often hide behind parameters that look harmless at first glance. Predictive AI helps uncover them earlier by examining how small variations ripple through the system, long before the first build reaches a test bench.

Once the model starts reacting to material choices, geometry shifts, or load expectations, early warning signals begin to surface. Some appear as repeated deformation patterns; others show up as unexpected stress concentrations or unstable responses under minor adjustments.

As teams move deeper into the analysis, several factors tend to shape where attention goes next, and transitional reasoning naturally pulls them together:

- Repeating anomalies, since behavior that breaks under small shifts often hints at a structural weak point.

- Unexpected parameter swings, especially when a component reacts far outside its predicted range.

- Designs that collapse rapidly, because sudden performance drops usually signal hidden instability.

Once those signals come into focus, the conversation inside R&D shifts as well. Instead of debating which direction might carry risk, teams already have a grounded reading of where problems will emerge. That awareness builds momentum, and each subsequent iteration gains more purpose because resources are no longer spent exploring paths that would have failed early in testing.

Reducing Design-to-Production Time Through Automated Insight Generation

The development cycle tightens considerably once automated insights begin shaping design work. At first, the model highlights which parameters most influence performance. As the system observes more iterations, however, its suggestions evolve from broad observations into targeted guidance. That shift matters because it changes how engineers prioritize their efforts. Instead of combing through raw reports, they move directly to the variants with the greatest potential.

As the workflow settles into that rhythm, several transitions begin happening almost naturally. Engineers compare design directions inside the same environment, analysts follow long-term behavior without stitching together separate datasets, and managers see early indications of how chosen designs will affect production constraints.

Over time, clusters of meaningful insights emerge, perhaps a geometry that consistently reduces stress spikes or a configuration that keeps thermal loads stable across a broader range. Each insight shortens the path between design and manufacturing by fading uncertainty and answering many of the questions that typically slow down pre-production reviews. By the time the design reaches the factory stage, most of the guesswork has already been resolved.

Real R&D Use Cases Where Digital Twin AI Delivers Measurable Savings

Across industries, digital twin AI delivers measurable savings by moving expensive physical tests into virtual space and revealing performance limitations early. In automotive R&D, virtual prototyping and simulation reduce the number of hardware builds needed and accelerate decision-making. Digital twins also support real-time condition modeling, helping engineers predict stress and failure without waiting for physical tests.

Integrating data from sensors and simulation models enables teams to refine designs continuously, shortening development cycles and reducing costs throughout product lifecycles. Growing academic and practical research highlights that high-fidelity digital twins unlock real savings by enabling engineers to replace trial-and-error testing with predictive, data-informed evaluation.

Automotive Component Prototyping and Durability Verification

Automotive teams face expensive trial-and-error cycles when physical prototypes fail durability or safety tests late in development. To address this, engineers increasingly rely on digital twin AI to simulate component behavior under real operating stresses before building any physical part.

Academic research shows how digital twin prototypes allow testing multiple configurations virtually and eliminate many iterations required on the shop floor. By mirroring how new parts behave, such as tracking data on temperature, load, and structural response, teams gain early insights on potential weak points. This significantly reduces material waste and the cost of repeated builds while maintaining performance confidence.

The primary ways digital twins help automotive R&D:

- Reduce physical tests. Virtual replicas take on much of the early testing burden.

- Accelerate feedback. Engineers see performance outcomes long before hardware exists.

- Improve design choices. AI models highlight durability risks early, cutting late redesigns.

Using digital twins early makes prototype behavior visible in advance, enabling engineers to adjust designs before any steel hits the workshop floor. That represents a clear, measurable savings not only in money but in development time.

Electronics Development Accelerated Through Thermal and Load Simulations

Thermal limits and mechanical loads are critical in electronics design, especially as devices get smaller and power densities rise. Traditional thermal testing requires multiple rounds of hardware builds, probes, and instrumentation, which costs time and money. Digital twin AI models change that by simulating heat, electrical loads, and other physics domains together, letting designers evaluate performance virtually.

Research covering Industry 5.0 and digital twin impacts in manufacturing highlights how simulation yields operational insights, reduces waste, and enhances quality in electronics production. In practice, these AI-driven models help engineering teams refine layouts to spread heat evenly, avoid hotspots, and meet reliability targets without waiting for physical validation cycles.

How simulation changes electronics R&D:

- Virtual thermal testing. Predict how heat migrates and concentrates before hardware exists.

- Multi-domain load simulation. Combine electrical and mechanical stresses to see real behavior.

- Faster iteration. Designers adjust and verify solutions in virtual space instead of building testers.

When electronics teams simulate combined thermal and mechanical behavior, they catch failure modes sooner and avoid costly late-stage fixes.

Reshape Your Manufacturing Process with AI, Digital Twins, and Program-Ace

Manufacturers looking to modernize their operations gain a clear advantage when AI and digital twins work together to streamline decisions, reduce validation cycles, and make production outcomes more predictable. Program-Ace supports that transition as an innovative solutions integrator, delivering tailored virtual environments that mirror real factory behavior and help teams correct issues before they appear on the floor.

Our specialists align the technology with practical objectives such as reducing testing overhead, improving throughput, and strengthening product reliability. Contact us and plan your transformation path without any further delay.