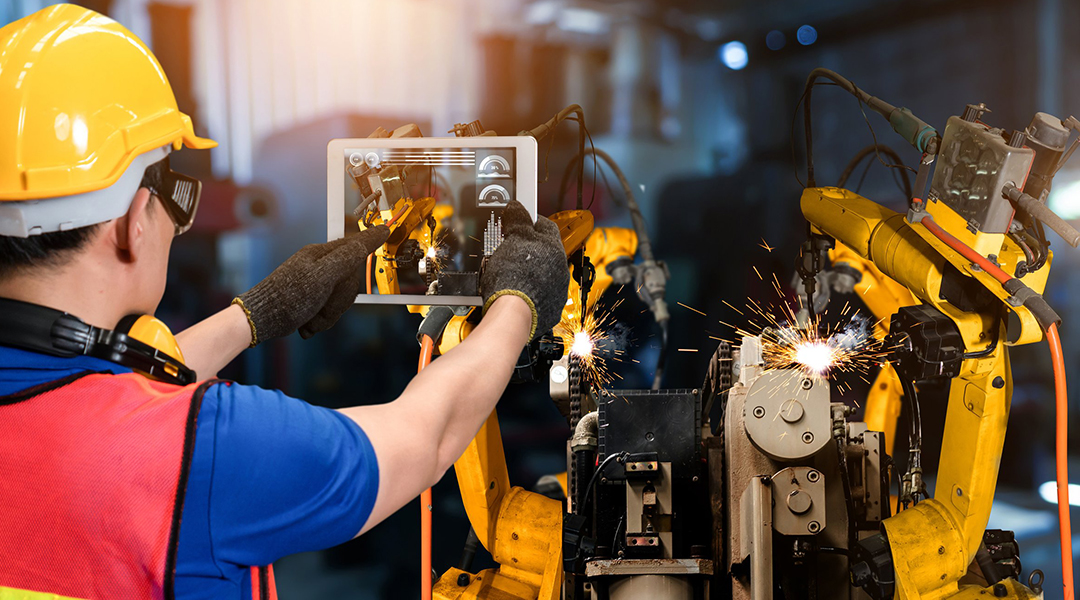

Preparing industrial teams for complex tasks requires practical training tools that match real equipment and real environments. Program-Ace now offers expanded virtual training solutions built around interactive 3D CAD models in VR. Instead of working with paper instructions or non-functional replicas, your teams can train in immersive environments that closely replicate the exact systems they will use on the job.

Virtual training solutions from Program-Ace combine realistic physical behavior, hands-on interaction, and process-specific logic. Each scenario is customized to match your equipment layout, operating procedures, and safety standards. Employees gain direct experience without interrupting production or waiting for machinery availability.

As part of our strategic partnership with LS Group, Program-Ace integrates the INTERACT plugin into immersive training and simulation solutions built in Unity. INTERACT is a powerful industrial-grade tool that enables real-time interaction with 3D CAD models in VR environments.

As part of our strategic partnership with LS Group, Program-Ace integrates the INTERACT plugin into immersive training and simulation solutions built in Unity. INTERACT is a powerful industrial-grade tool that enables real-time interaction with 3D CAD models in VR environments. It brings highly realistic physics, ergonomic analysis, and collaborative features to virtual spaces, making it an ideal foundation for simulation-based learning.

With our Unity expertise and LS Group’s robust technology, your teams gain access to scalable, high-performance VR training environments built on real-world data and processes.

Why Conventional Training Holds Teams Back

When your team trains using outdated materials or classroom-only sessions, there’s often a gap between what they learn and what they need to do. Program-Ace works with companies facing this exact issue: operators who understand the theory but struggle with execution.

Static materials and limited access to equipment slow down onboarding and increase the chances of mistakes. Our team helps bridge that gap by offering realistic, repeatable training environments that mirror your workflows. You get training tools that support real roles, using the same systems your team already relies on in the field.

Static Formats Don't Support Hands-on Performance

Your employees can't become proficient by watching slides or reading PDFs. They need time inside real procedures. However, most training programs rely on passive materials, one-off demos, or instructor-only walkthroughs. That approach limits how much your team can apply in real environments.

Program-Ace often sees teams hit barriers like:

- No access to real tools. In many facilities, equipment is always in use or unsafe to train on directly.

- No room for mistakes. Employees are expected to perform without ever testing what failure looks like.

- No tailored repetition. After a session ends, there's no simple way to revisit or retry key steps.

- No procedural feedback. Traditional formats don't track how well a task is performed or where errors happen.

Without structured practice tied to actual systems, people forget steps or freeze in complex situations. That slows down operations and increases supervision time. Our team develops virtual training environments where your employees interact with full workflows, apply decisions, and repeat sequences until they're ready to move forward. Consistency matters when your work involves precision and risk.

Real Systems Carry Real Risk for New Staff

When someone new joins your team, they need to learn fast without disrupting daily operations. However, giving them access to real equipment is often not possible. Machines are in use, the environment may be hazardous, or errors could lead to downtime. Your company shouldn't have to choose between speed and safety.

Some of the most common bottlenecks we hear from clients include:

- Emergency scenarios never get practiced. You can't rehearse rare but critical situations using live equipment.

- Validation happens too late. Teams often test workflows only after they're in production, which creates avoidable problems.

- Onboarding is inconsistent. Not every shift or group gets the same level of hands-on time.

At Program-Ace, we support teams that need scalable, safe, and effective ways to build skills before stepping onto the floor. Our virtual training solutions enable every employee to train on exact models of your systems. When your staff practices in conditions that match your own, they make fewer mistakes and start contributing faster.

Transform your 3D CAD data into simulation-ready VR training tools with Program-Ace.

Program-Ace Expertise and Benefits for Clients

Every company has its own procedures, equipment layout, and safety protocols. Program-Ace does not offer one-size-fits-all training tools. We help you develop fully interactive environments that reflect how your teams actually work. That includes how parts are assembled, how systems behave under pressure, and how errors are identified and corrected.

Our developers adapt each solution to the systems, inputs, and processes already used by your teams. You get a high-fidelity experience that directly supports performance goals, with custom logic, realistic physics, and layout-accurate content across every session.

Every Solution Fits the Way Your Operations Work

When your team starts using a virtual training application built by Program-Ace, they are not dropped into a generic simulation. Every detail matches your internal logic, safety standards, and procedural structure. We work from your CAD data, process charts, and real-world feedback to build simulations that feel familiar and act predictably.

Some ways your company benefits from this are:

- Training content follows your own workflows. Nothing is generic or assumed.

- Visuals are based on your real assets. CAD data is transferred directly into the virtual environment.

- Interaction logic is built around your steps. Users complete tasks as they would in the field.

- Safety systems are configured according to your standards. Fail-states and edge cases reflect actual conditions.

Our experts configure each scenario to reflect what happens inside your facilities. That includes movement restrictions, control behavior, custom machinery, and multi-user collaboration. When your team steps into VR, they already know what to expect.

Clients See Value Across Safety, Timing, and Performance

When it comes to VR in education, it’s not enough to complete the training once. Your teams need consistency, repeatability, and relevance every time they enter a session. Program-Ace focuses on building scenarios that scale across job roles and shift schedules. No extra equipment is required, and no production systems need to be taken offline. You train people faster without sacrificing context or accuracy.

Results our clients often achieve are:

- Reduced downtime during onboarding. Employees reach baseline competency faster.

- Higher retention of critical procedures. Repetition is easy and built into every solution.

- Fewer operational mistakes. People train with accurate systems, not abstract instructions.

- Lower supervision needs. Trainers no longer repeat the same steps for every new hire.

Your company stays productive while preparing new staff for technical work. There is no need to reconfigure equipment or coordinate special access. The training matches your machines, follows your logic, and reflects the challenges your teams face every day. That is how performance improves over time.

What INTERACT Adds to Your VR Training Environment

Program-Ace integrates INTERACT into your Unity-based training applications to give your teams a more complete, controlled environment for hands-on learning. INTERACT allows your engineers, technicians, and operators to interact with real CAD assemblies using realistic behavior and precise logic.

The table below shows how key INTERACT features directly impact real training goals:

| INTERACT Feature | What It Enables |

| Real-time 3D CAD visualization | Users work directly with accurate, scalable digital models of your equipment. |

| Physically accurate simulation (XDE) | Interactions follow real-world physics, including joint damping and collision logic. |

| Ergonomic posture analysis | Safety teams can test reach, posture, and movement without external tools. |

| Custom scenario creation | Our team builds specific training flows tied to your equipment and procedures. |

| Haptic device integration | Users feel resistance and motion during virtual interactions. |

| CAVE rendering support | Teams view large-scale layouts across physical immersive setups. |

| Point cloud integration | Digital spaces reflect real environments from your scans. |

| Multi-user collaboration tools | Teams can train together across departments and locations. |

We align every one of these features with the work your staff performs daily, removing the guesswork and giving your company a focused, repeatable training solution.

A Reliable Plugin Built for Industrial Performance

Many training platforms break under the pressure of real-world use cases, such as heavy assets, complex physics, or device requirements. INTERACT is designed to support high-performance industrial training without cutting corners. Our developers work directly with your CAD data, Unity environment, and target hardware to make sure the full training solution performs as expected.

The latest 2025.2 release of INTERACT brings even more stability and precision with:

- Continuous collision detection (CCD). Fast-moving parts interact without glitches or overlap.

- Broadphase filtering. Performance improves during complex simulations with large assemblies or cable networks.

- Custom hierarchy icons. Teams identify and manage parts of the scene faster.

- Virtual object grabbing. Ergonomics testing now supports direct interaction through virtual hands.

- Post-installation checks. Compatibility is validated with current Unity render pipelines.

We tailor the plugin’s use to your workflows and add the configurations your team needs. That includes enabling or disabling physics properties, customizing interaction logic, and integrating ergonomic and visual standards.

Applications Across Industrial Sectors

Virtual training must match the technical and operational complexity of each industry. At Program-Ace, we work with manufacturing leaders, energy providers, equipment builders, and defense organizations to create VR-based training programs based on real procedures and assets. Every solution uses your existing CAD data, safety protocols, and internal processes.

We don't assume what your teams need. We replicate your workflows and adjust the training environment to fit each role, from assembly specialists to emergency response technicians. The exact simulation can support maintenance tasks, safety walkthroughs, equipment familiarization, and cross-team collaboration across departments.

Training Programs That Match Sector-Specific Requirements

We do not apply the same approach to every industry. Your goals, equipment types, and regulatory requirements are unique, and your training program must reflect that. Program-Ace delivers targeted simulation environments designed to support your internal priorities across every team and function.

Program-Ace works with companies across technical, commercial, and defense sectors to integrate 3D CAD-based VR training into real operations. Below is a breakdown of how each industry listed can benefit from our virtual training solutions:

| Industry | Benefits of 3D CAD VR Integration |

| Military & Defense | Safe simulation of tactical procedures, multi-role collaboration, and equipment handling in controlled environments. |

| Oil & Gas | Training on remote equipment, hazardous scenarios, and complex maintenance procedures without physical risk. |

| Telecom | Network hardware interaction, spatial planning for installations, and technician onboarding in immersive formats. |

| Manufacturing | Full assembly process simulation, equipment testing, and training for complex mechanical workflows. |

| Healthcare | Tool-based movement analysis, procedure walkthroughs, and ergonomic task simulation for medical and lab settings. |

| Construction | Structural assembly planning, site safety orientation, and sequencing of on-site workflows in digital spaces. |

| Logistics | Material flow visualization, warehouse system training, and worker interaction with transport equipment. |

| Retail | Fixture planning, equipment training for POS systems, and space layout validation in simulated stores. |

| Marketing & Advertising | Interactive product demos, experiential installations, and environment testing using accurate brand assets. |

| Energy & Utilities | Control room procedures, high-voltage interaction practice, and plant layout understanding through immersive sessions. |

Real-World Use Cases from Our Industrial Clients

You do not need to expose new staff to real risks to build job-ready experience. Program-Ace develops VR training programs that simulate hands-on procedures, technical routines, and hazard response using accurate 3D CAD assemblies and real-time physics.

Across industries, our clients use these solutions to prepare teams for complex operations and edge-case scenarios that cannot be safely rehearsed on-site. The goal is not just to watch or observe but to do the work virtually, from start to finish.

Some of the most common applications are:

- Practicing emergency operations. Employees run through electrical incidents, fall risks, or hazardous exposure drills safely and repeatedly.

- Simulating process-driven maintenance. Staff follow detailed equipment routines under realistic system conditions.

- Handling specialized machinery. Technicians interact with compressors, separators, or switchgear inside immersive spaces.

- Improving ergonomic performance. Teams test lifting, movement, and posture using configurable avatars and real object behavior.

- Completing technical inspections. Operators work through pre-trip and on-site checklists using full-scene logic and digital instrumentation.

Your company can train entire teams using immersive sessions that replicate the job without exposing anyone to real consequences. Every action in the simulation prepares users for what happens next in the field.

Ready to Bring Real-World Precision into Virtual Training?

At Program-Ace, we help companies move beyond generic content and build immersive training solutions grounded in their real operations. As an innovative solutions integrator, we combine deep industry knowledge, 3D CAD expertise, and VR development to deliver scalable, simulation-based training environments that mirror your exact tools, procedures, and safety protocols.

Our approach transforms your CAD models into fully interactive digital environments, complete with realistic physics, tailored interaction logic, and repeatable workflows. This enables your teams to train with confidence, develop skills faster, and minimize real-world risk without disrupting production.

Whether you need to onboard faster, improve safety, or prepare staff for complex equipment handling, we’re here to help you design a training experience that reflects how your people actually work.

Contact us to explore VR training solutions tailored to your operations.