Virtual simulation solutions have become essential for improving operations in the oil and gas industry. They allow you to replicate complex processes, analyze potential scenarios, and identify inefficiencies without interrupting ongoing work. These tools offer precise data insights, enabling better decisions about resource management, risk mitigation, and process optimization.

You can use simulation to test strategies for refining operations, manage risks in exploration, and enhance safety in day-to-day activities. For example, real-time simulations help identify potential hazards in equipment maintenance or process flow. Such insights allow quicker adjustments, reducing downtime and preventing costly mistakes.

Focusing on compatibility with existing systems ensures a smoother transition when implementing virtual simulation solutions. Look for customizable software to fit your specific operational needs, whether for upstream, midstream, or downstream processes. By leveraging these capabilities, you achieve both operational efficiency and cost savings.

Why Simulation Matters in the Oil and Gas Industry

Simulation plays a crucial role in helping you address operational challenges effectively. From refining processes to safety protocols, it enables precise analysis and strategic decision-making. Different types of simulation training focus on specific needs, such as equipment handling, process optimization, and emergency response. These tools are essential for improving safety, reducing costs, and enhancing efficiency across operations.

Enhancing Decision-Making with Oil and Gas Simulation

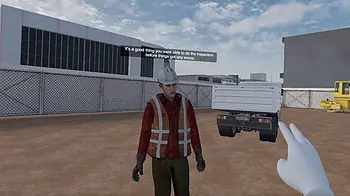

VR training solutions for oil and gas provide an interactive and controlled environment for you to test various scenarios without operational interruptions. These solutions are highly beneficial for enhancing decision-making, replicating real-world challenges, and enabling better preparation.

Some of the benefits of simulation for decision-making include:

- Data-driven insights. Simulations offer real-time analytics for evaluating outcomes and improving operational efficiency.

- Scenario testing. You can test different strategies in simulated environments to identify the best approach without financial or safety risks.

- Skill enhancement. Interactive modules ensure that your team is better equipped to handle complex processes and emergencies.

Applying VR training solutions allows for immersive learning experiences that bridge the gap between theoretical knowledge and practical application. By simulating complex scenarios in a risk-free environment, you gain valuable insights and prepare your team to tackle real-world challenges confidently. Improved decision-making directly impacts operational efficiency, cost control, and safety outcomes, ensuring long-term benefits for your processes.

Reducing Risks Through Advanced Simulation Models

Advanced simulation models offer tools for addressing operational hazards and improving safety outcomes. For example, process simulation helps identify vulnerabilities in refining and drilling operations, enabling proactive adjustments.

How simulation reduces risks:

- Hazard identification. Predictive models help you identify and address potential safety hazards before they escalate.

- Emergency preparedness. Simulations prepare your team to respond effectively to fires, spills, and equipment failures.

- Operational consistency. Consistent modeling reduces errors caused by human factors or unexpected changes.

Simulation models provide the precision required to minimize exposure to operational hazards and unforeseen failures. Proactively identifying weaknesses in workflows or equipment ensures immediate action to safeguard employees and infrastructure. Integrating advanced tools into your processes establishes a safety-first culture, reduces downtime, and delivers measurable improvements across all critical operations.

Key Features of Oil and Gas Process Simulation Software

Oil and gas process simulation software equips you with advanced tools to model, analyze, and optimize complex workflows. From enhancing process efficiency to improving safety protocols, these solutions offer practical benefits for a variety of operations. Effective simulation training examples, such as equipment handling and emergency response drills, showcase how simulation can drive measurable improvements in operational outcomes.

Modeling Complex Operations for Greater Efficiency

Managing complex operations effectively demands precision tools that replicate workflows and enable process refinement. Simulation software provides actionable insights by identifying inefficiencies, testing strategies, and simulating various operational scenarios. Through these capabilities, you can achieve greater efficiency, streamline workflows, and ensure optimized performance, even under challenging conditions or fluctuating demands.

Examples of how modeling enhances operations include:

- Process optimization. Eliminating inefficiencies through detailed analysis results in smoother production cycles and cost savings.

- Equipment performance analysis. Predictive simulations evaluate machinery under diverse conditions, helping you avoid costly breakdowns and schedule maintenance.

- Scenario testing. Testing different strategies in a risk-free environment prevents errors and optimizes decision-making.

Simulation models provide a foundation for consistent and reliable operations, empowering you to refine resource allocation, reduce downtime, and maintain high performance. Leveraging advanced modeling tools improves operational resilience while ensuring long-term productivity and profitability.

Real-Time Data Integration and Predictive Analysis

Integrating live data into oil and gas operations delivers up-to-date insights essential for informed decision-making. Simulation software with real-time data capabilities enables proactive management of unexpected issues and enhances overall operational performance. The predictive analysis complements this by identifying potential risks, allowing teams to take preemptive actions and maintain efficiency.

Applications of real-time data and predictive tools include:

- Immediate insights. Real-time monitoring ensures quick adjustments to production or resource challenges.

- Accurate forecasting. Future trends and risks can be predicted, aiding strategic planning and minimizing disruptions.

- Improved collaboration. Shared real-time insights across teams eliminate delays and improve overall workflow synchronization.

Combining real-time data integration with predictive analytics strengthens your ability to respond confidently to industry challenges. These capabilities help optimize processes, reduce risks, and enhance collaboration, ensuring you achieve consistent, reliable results across all stages of operations.

Types of Oil and Gas Simulation Solutions — From Exploration to Refining

All stages of the oil and gas production process, from discovery to refining, may be adequately represented by the industry's simulation systems. You may evaluate plans, enhance processes, and increase safety standards with these tools, including reservoir modeling and operational training. Reduce potential problems, boost productivity, and accomplish your operational objectives with the help of tailored simulation solutions.

Reservoir Simulation: Unveiling Opportunities Beneath the Surface

Accurately assessing subsurface conditions is crucial for optimizing resource extraction. Reservoir simulation provides advanced models that replicate geological formations, enabling you to evaluate reservoir characteristics and predict behavior over time. Through detailed fluid flow analysis and pressure simulations, you gain a clearer understanding of reservoir dynamics and maximize recovery rates with minimal environmental impact.

Some of the benefits of reservoir simulation are:

- Precise resource estimation. Advanced models offer reliable data on fluid distribution and reservoir capacity.

- Strategic drilling decisions. Identifying optimal drilling zones improves resource extraction efficiency.

- Risk mitigation. Simulations predict potential issues like reservoir compaction, helping you take preventive measures.

- Enhanced field development planning. Models support long-term strategies for maximizing profitability and sustainability.

Reservoir simulations empower you to make evidence-based decisions by providing actionable insights into subsurface conditions. Leveraging these models reduces exploration risks, ensures efficient resource extraction, and contributes to more sustainable operations across upstream activities.

Process Optimization with Oil and Gas Process Simulation

Optimizing production processes demands a precise approach, and process simulation tools provide detailed insights to improve operational efficiency. These tools model workflows in refining, transportation, and distribution, enabling you to identify bottlenecks, improve throughput, and optimize energy usage. Real-time adjustments supported by simulation allow seamless integration into your existing operations.

Applications of process simulation include:

- Refinery optimization. Simulations detect inefficiencies in refining processes, ensuring improved product output.

- Energy efficiency improvements. Analyzing energy consumption patterns supports efforts to reduce costs and emissions.

- Transport and logistics planning. Coordinating supply chain activities minimizes delays and optimizes delivery schedules.

- Production scaling. Scenarios modeled in simulations ensure smooth transitions when scaling production to meet demand changes.

Integrating process simulations into your workflows enables consistent production outcomes and efficient resource use. A detailed understanding of process dynamics allows you to respond proactively to challenges while meeting operational objectives effectively.

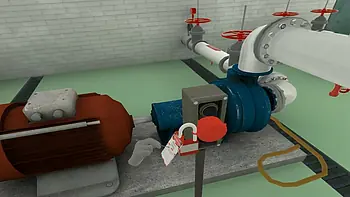

Training and Safety Simulations for Operational Excellence

Workforce safety and operational readiness are critical in the oil and gas industry. Training simulations create realistic environments where your team can practice emergency responses and improve technical skills without operational risks. Through immersive learning, employees gain the confidence to handle high-stress scenarios effectively.

The examples of training and safety applications include:

- Fire and spill response. Simulations prepare teams to act decisively in emergencies.

- Equipment usage training. Operators develop expertise in handling machinery with greater precision.

- Worksite hazard assessments. Practical scenarios teach proactive identification and mitigation of risks.

- Emergency evacuation drills. Teams learn safe and efficient evacuation procedures tailored to facility layouts.

Adopting training simulations ensures your workforce is prepared for critical challenges, leading to safer operations and fewer incidents. By prioritizing safety training and skill development, you build a resilient, capable team capable of addressing any operational risks.

Boost your operations with our oil and gas simulation solutions!

How Oil and Gas Simulation Software Drives Profitability

Maximizing profitability in oil and gas operations requires a strategic approach to managing resources, processes, and risks. Simulation software supports profit-driven decisions by modeling complex workflows, optimizing resource allocation, and identifying cost-saving opportunities. Detailed scenarios reduce inefficiencies while improving production outcomes, helping you stay competitive and achieve consistent financial growth.

Cost Savings Through Operational Efficiency

Operational efficiency plays a pivotal role in reducing expenses and improving overall profitability. Simulations replicate intricate processes, allowing you to identify bottlenecks and optimize workflows. Significant cost reductions can be achieved without compromising output quality by pinpointing specific inefficiencies in equipment usage or production cycles.

Incorporating predictive capabilities allows proactive maintenance planning, which minimizes downtime and prevents costly breakdowns. Additionally, real-time analysis of production variables enhances decision-making, leading to resource allocation strategies that cut unnecessary spending.

Cost savings also depend on maintaining consistency across operations. Process simulations make it easier to manage fluctuations in demand while avoiding overproduction or waste. Operations can then meet objectives more sustainably while ensuring that budgets are met. The ability to adapt quickly to challenges contributes to creating a scalable and profitable business environment.

Accelerating Innovation and Scalability with Simulations

Scaling operations while fostering innovation is often a challenge in the competitive oil and gas sector. Simulation software facilitates this process by offering a dynamic platform for testing new strategies and introducing efficiencies at various stages of production.

Experimenting with innovative techniques in virtual environments reduces risks while ensuring informed decisions are made regarding their feasibility. Simulation models allow you to adapt to market demands faster by assessing changes in production requirements.

Efforts to scale also benefit from simulation-based collaboration, as real-time data sharing improves coordination among teams. Operations can expand seamlessly when simulations guide the integration of new systems and processes.

Adaptability becomes a key strength, enabling sustainable growth while maintaining control over resource use and expenses. The approach not only accelerates progress but also fosters long-term competitive advantages.

Choosing the Right Oil and Gas Simulation Software

Selecting simulation software requires focusing on specific operational challenges and business goals. Understanding key features and assessing adaptability to diverse scenarios ensures better results. Tailored solutions offer tools for optimizing processes, managing risks, and improving decision-making, ultimately supporting operational excellence and long-term success in the oil and gas industry.

Evaluating Software Capabilities for Diverse Operational Needs

Assessing simulation software begins with analyzing its ability to address different aspects of oil and gas operations. Solutions that cater to exploration, refining, and logistics provide greater value by accommodating the unique demands of each phase. Software that integrates real-time data enables dynamic adjustments to production and workflow management, ensuring relevance in varying conditions.

Important evaluation factors include:

- Scalability. Software must adapt to changing production demands or operational expansions.

- Accuracy. Simulation models should deliver precise results for better decision-making.

- Integration. Compatibility with existing systems streamlines implementation and daily usage.

By carefully analyzing the available solutions, you can pick software that can manage complicated activities and provide quantifiable productivity gains. Such a choice minimizes risks, maximizes cost efficiency, and supports sustainable growth.

Customization Options for Specific Simulation Requirements

Specific operational challenges often require tailored solutions to achieve desired outcomes. Customization options in simulation software enable configurations suited to unique workflows, equipment specifications, or safety protocols. Incorporating features such as scenario modeling or industry-specific metrics ensures the software aligns with operational priorities.

Benefits of customizable simulation solutions include:

- Tailored modeling. Configurations match your unique processes, enhancing accuracy and efficiency.

- Industry-specific insights. Features designed for oil and gas offer actionable data relevant to operations.

- Enhanced flexibility. Adjustable parameters allow for quick adaptation to new challenges or goals.

Customized solutions provide a more effective foundation for addressing complex needs in exploration, refining, or logistics. Investments in software that accommodates your specific requirements lead to smoother operations and a stronger competitive position in the industry.

Challenges in Implementing Oil and Gas Simulation

Integrating oil and gas simulation software comes with unique challenges that require careful planning. Each step must address potential risks, from compatibility with legacy systems to user adoption hurdles. Identifying these obstacles early ensures smoother implementation and helps you realize the full potential of simulation tools in improving operations.

Overcoming Integration Hurdles in Legacy Systems

Compatibility with legacy systems often becomes a significant obstacle during software implementation. Older infrastructure can lack the necessary flexibility to integrate modern simulation technologies seamlessly. Proper assessment of current systems and identifying areas for upgrades are critical steps to overcome this issue. Detailed integration plans tailored to your existing technology landscape minimize disruptions and ensure functionality remains intact during the transition.

Steps to address integration challenges include:

- System evaluation. Analyze existing infrastructure for compatibility gaps.

- Phased implementation. Introduce simulation software gradually to reduce operational risks.

- Collaboration with experts. Work with experienced integrators to align new solutions with legacy systems.

Investing time and effort in overcoming integration challenges enhances operational efficiency and ensures your simulation strategy's long-term success. Solutions that effectively bridge the gap between old and new systems offer a stable foundation for continuous improvements.

Managing User Adoption for Seamless Transition

Introducing simulation software requires users to adapt to new tools and workflows, which can create resistance or slow down implementation. Clear communication about the benefits and practical training sessions are crucial for encouraging adoption. Providing accessible resources and addressing user concerns early fosters a smoother transition and boosts confidence in the new system.

Strategies for improving user adoption include:

- Tailored training programs. Focus on specific user roles and their responsibilities within the simulation process.

- Regular feedback loops. Gather input from users to refine training and support.

- Clear communication. Highlight tangible benefits like efficiency gains and risk reduction.

Successful adoption depends on aligning the software’s capabilities with user needs and providing adequate support throughout the transition. Building trust in the system ensures teams are confident in leveraging simulation for daily operations, maximizing its impact on organizational efficiency.

Oil and Gas Simulation Software with Program-Ace

Program-Ace delivers cutting-edge simulation software tailored to address the unique challenges of the oil and gas sector. As an innovative solutions integrator, our expertise spans areas like process optimization, real-time data analysis, and training simulations. With a focus on meeting specific operational needs, we collaborate closely to create solutions that maximize efficiency, reduce risks, and drive profitability.

Our team ensures seamless integration into your existing workflows, providing the flexibility to adapt to evolving business requirements. Whether you need tools for refining processes or advanced safety simulations, Program-Ace has the experience and resources to deliver impactful results. Contact us to learn how our oil and gas simulation solutions can transform your operations and achieve measurable results.