Digital twin solutions are transforming the way industries plan, monitor, and optimize their operations. Instead of relying on static models, organizations can now work with real-time environments that integrate accurate data, photorealistic context, and interactive features. Construction projects, energy grids, transportation systems, and defense applications already use these technologies to reduce risks and improve efficiency.

The value of digital twin solutions lies in their ability to quickly connect different data sources into a single, cohesive view. Geospatial information, BIM files, IoT feeds, and simulation results no longer remain separate silos. When combined, they provide a single environment where stakeholders can test scenarios, validate assumptions, and reach decisions with confidence.

Enterprises adopting this approach report clear gains: faster planning, fewer delays, and stronger collaboration across teams. Industry recognition demonstrates that digital twins are no longer limited to experimental pilots but are becoming a standard component of large-scale projects. The next step for many organizations is learning how to apply them at scale with the right balance of performance and usability.

Why Digital Twins Are Becoming Essential Today

Regardless of the type of digital twins you opt for, the tech is gaining urgency because teams need live models that reflect change, not static snapshots. They connect design data, geospatial context, and operational signals into one place where people can check status, test options, and agree on actions. Costly surprises are avoided when issues are identified early in a shared view. Approvals move faster when stakeholders see measurable effects.

From the projects we have delivered, it became clear that value grows when a twin links planning, construction, and operations, rather than serving a single phase. In the long run, you’ve got fewer delays, better coordination, as well as more transparent accountability across owners, contractors, and public authorities over time.

Moving Beyond Traditional 3D Models

Traditional 3D models freeze a moment in time. They require manual updates, break when source data changes, and rarely align with field conditions. Digital twins replace that brittleness with a live model tied to authoritative data sources. Teams see geometry, metadata, and time-series signals in one view, so issues surface before they lead to rework. According to our internal analysis, the most substantial gains appear when design, schedule, and operations share the same spatial context.

- Static. Legacy models show shape but lack trustworthy state and history. So, a twin records versions, events, and sensor input so people can trace cause and effect.

- Isolated. Files live in separate tools. A twin links BIM, GIS, and IoT, which removes conflicting spreadsheets and fragmented comments.

- Reactive. Problems appear late in the cycle. A digital twin forecasts clashes, capacity limits, and safety risks while changes are still cheap.

Field teams read the same data as planners, so site decisions match design intent. Owners map KPIs to locations, which turns a model into a dashboard for cost, schedule, and quality. APIs let contractors push updates from equipment, inspections, and material deliveries, keeping the digital twin aligned with reality. Data stays current without manual file exchanges forever.

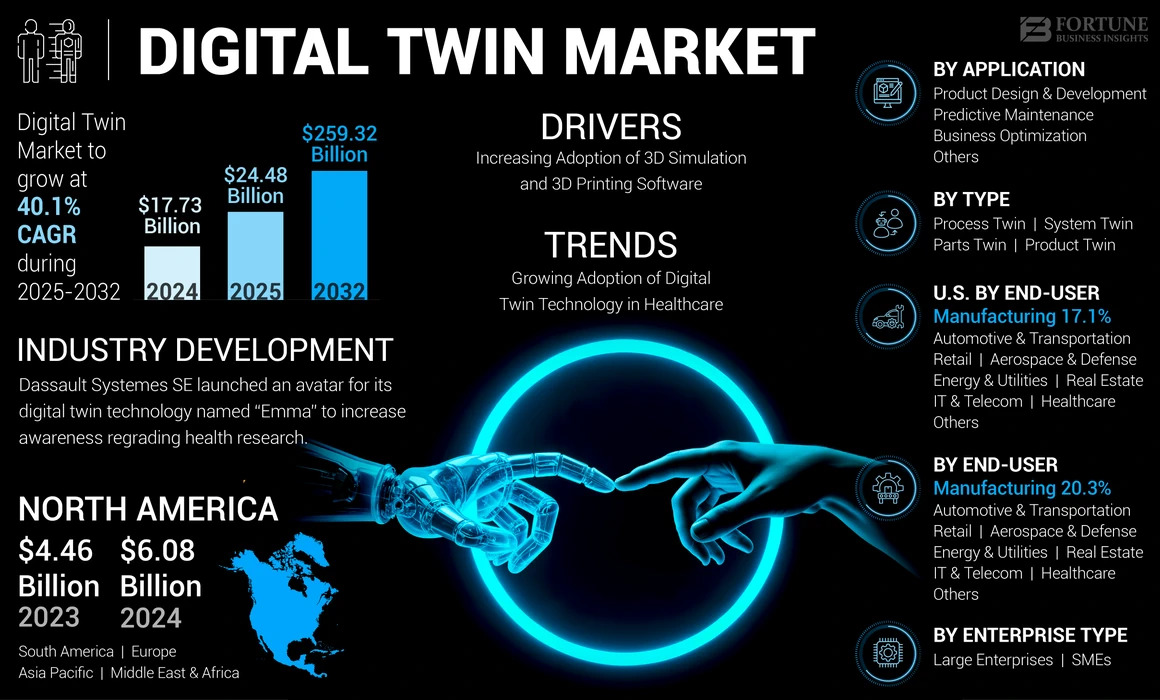

Market Growth and Technology Maturity

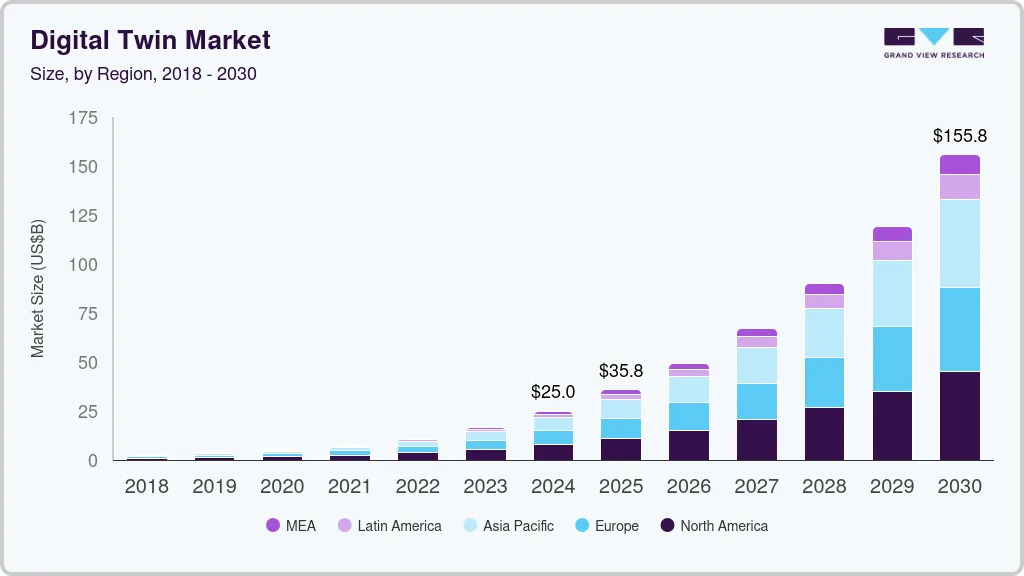

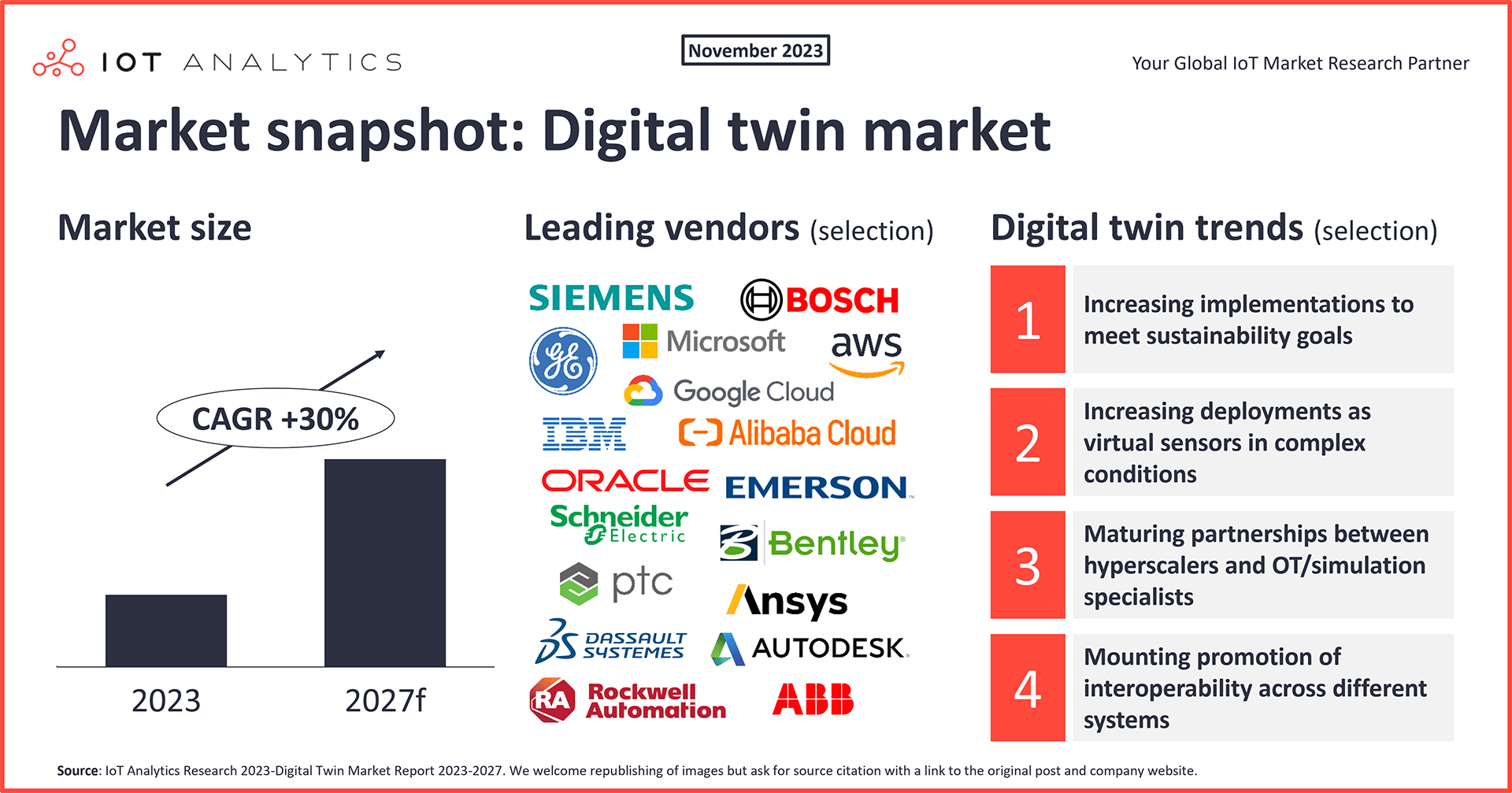

Many clients ask whether digital twins are still experimental or ready for serious deployment. The data shows they are clearly maturing. According to independent reports, the global digital twin market is projected to grow from $24.48 billion in 2025 to $259.32 billion by 2032, at a CAGR of 40.1 %. Other sources, such as Grand View Research, estimate growth at 34.2% CAGR through 2030, reaching approximately 155.84 billion by then.

Growth doesn't rely just on hype. Organizations are now running large-scale pilots that become production systems. According to IoT Analytics, approximately 29% of global manufacturing firms have at least partially implemented digital twin strategies. Practical experiments confirmed that streaming geospatial data, IoT feeds, and engineering models into unified twins can outperform siloed systems.

Maturity comes from three reinforcing trends:

- Open standards. Formats and protocols like 3D Tiles reduce custom work and allow geospatial, BIM, and real-time tools to interact.

- Efficient streaming. Selective loading, level-of-detail tiling, and smart caching keep performance stable across scales.

- Cloud and edge infrastructure. Scalable compute and localized processing let twins support many users without lag or bottlenecks.

So, as our tests show, mature pipelines let teams move from proof-of-concept to mission-critical systems in a fraction of earlier timelines.

Which Sectors Are Driving Adoption

More organizations are turning to digital twin solutions when they see clear, measurable value in real-world settings. Use cases that cut costs, shorten downtime, or improve safety tend to lead to adoption.

At the Port of Corpus Christi, Texas, a digital replica called OPTICS tracks ship positions and runs emergency simulations using live and historical data. In Jacksonville, Florida, city planners constructed a waterfront twin to simulate storm surge scenarios and had emergency responders practice their response preparations.

Below we've compiled a couple of sectors showing strong traction:

- Construction. Teams simulate phasing, logistics, and clash detection in context, reducing errors in complex sites.

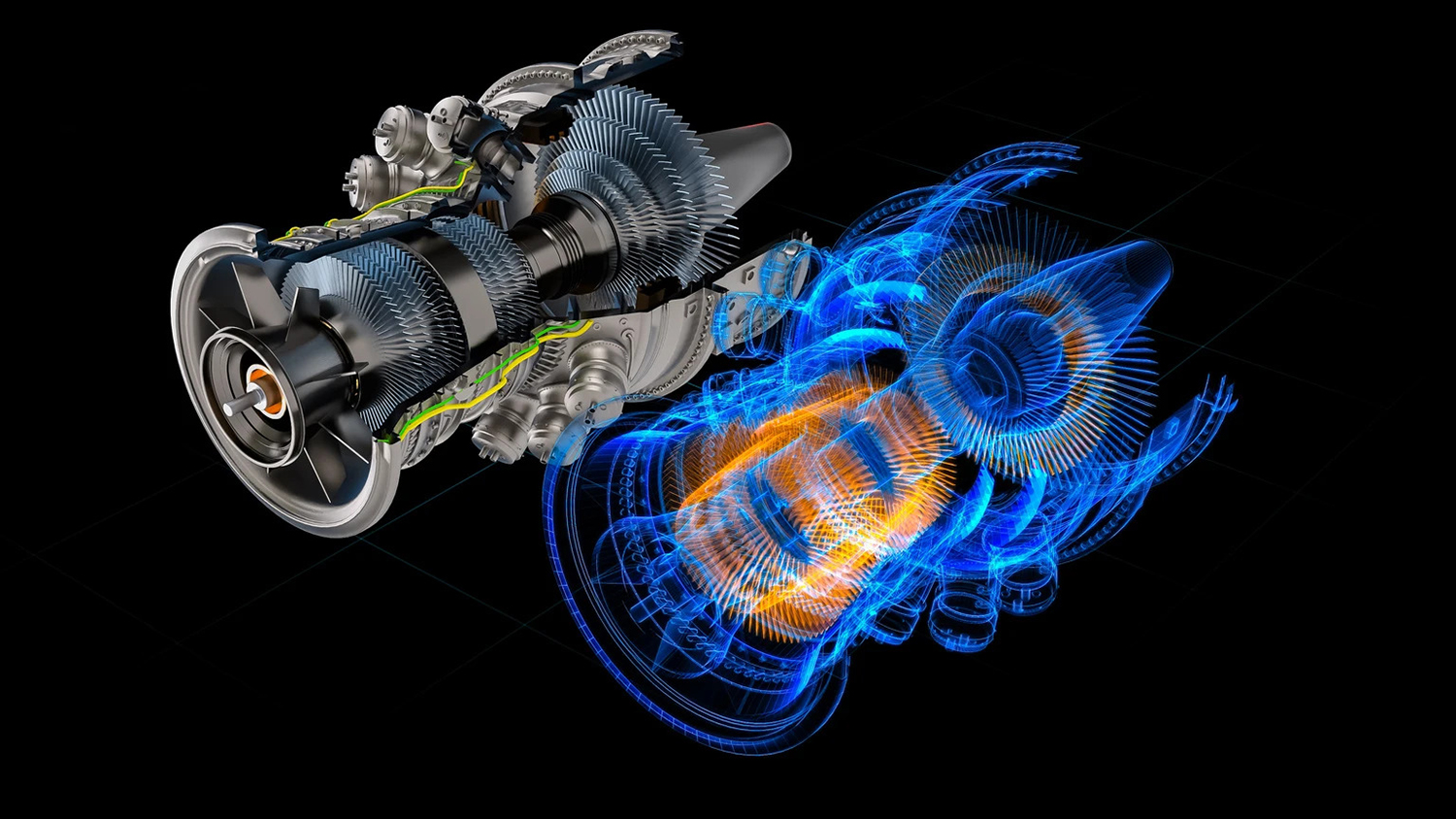

- Energy & utilities. Operators monitor substations, pipelines, turbines, or grids in near real time to predict failures and optimize output.

- Transportation & infrastructure. Rail, ports, and roads use twins to test capacity, manage flow, and plan maintenance with spatial accuracy.

Cities, mining, and insurance are also picking up use. Adoption across enterprises shows that the twin technology no longer belongs solely to pilots, as it's now part of infrastructure planning and operations.

Cesium as the Core of Geospatial Experiences

Cesium powers the spatial side of digital twins by managing location, terrain, imagery, and 3D content as one synchronized whole. Rather than juggling multiple systems for maps, models, and context, Cesium lets developers treat them as a unified layer. From our experience, projects that center around Cesium avoid common pitfalls in alignment and scale because the geospatial foundation already handles projection, precision, and streaming. Its open-standard orientation also reduces friction when you combine data sources or shift between tools.

Streaming Data with the 3D Tiles Standard

Efficient streaming is critical when your model covers a city or a facility. Cesium's 3D Tiles standard slices large 3D content into spatially indexed segments, so clients fetch only what's needed. 3D Tiles is an OGC Community Standard. Tiles support photogrammetry, BIM, point clouds, terrain, and instanced features, thereby mixing them in a unified dataset.

Extensions in "3D Tiles Next" enhance semantic metadata and spatial indexing, making the format more powerful for simulation and filtering. Our internal analysis shows that streaming via 3D Tiles reduces initial load times by 40–60 % compared to naïve tiling approaches in many test cases.

Managing Large-Scale Models in Real Time

Handling millions of 3D features over large areas is daunting. Cesium utilizes level-of-detail (LOD) hierarchies, frustum culling, and spatial tiling, ensuring that only visible and relevant content consumes processing resources.

Real-world projects prove that this works: at Penn's Landing I-95 CAP in Philadelphia, Cesium for Unreal helped convert civil infrastructure models into interactive digital twins, cutting rendering times for city-scale scenes from hours to minutes.

Our tests demonstrate that maintaining frame rates above 30 fps is feasible even when processing complex geometry, textures, and live sensor feeds across large zones.

Developers can also stream updates (e.g., structural changes, sensor data) tile by tile rather than reloading a complete model, which keeps runtime responsiveness.

Open Standards that Enable Collaboration

Open formats and protocols let multiple teams, tools, and domains work together smoothly. Cesium led the creation of 3D Tiles as an open standard, then worked with the geospatial community to adopt it. Since 3D Tiles builds on glTF, interoperability with design tools, engines, and GIS systems becomes simpler.

One example is QGIS (an open-source GIS tool) now supporting the loading of Cesium 3D Tiles, thereby bridging the gap between spatial analysis and 3D visualization. Open standards ease collaboration across architecture, engineering, GIS, and operations teams. In our professional work, we've seen how removing custom format barriers accelerates integration and reduces errors during handoffs between teams.

Reach out to our Cesium Certified developers

Unreal Engine and the Power of Real-Time Visualization

Unreal Engine-based digital twins can be a game changer. The framework’s rendering capabilities turn raw geospatial or engineering data into detailed, interactive environments that people can explore naturally. From our experience, the advantage lies not only in photorealism but also in how smoothly the engine handles complex datasets once integrated with Cesium. Decision-makers value the ability to see projects exactly as they would appear on site, making discussions more productive and outcomes more precise.

Photorealism and Performance at Scale

Digital twins gain credibility when they look and behave like a tangible asset. Unreal Engine achieves this through advanced lighting models, dynamic shadows, reflections, and physically based materials. Environments can replicate surfaces of concrete, glass, or steel so convincingly that stakeholders feel they are standing within the site.

Performance matters just as much as fidelity. The engine relies on modern GPU techniques such as instancing and virtual textures, which allow vast urban models or massive facilities to run smoothly. Developers can combine billions of polygons into optimized clusters that adjust detail depending on the viewer's position.

Consider the following aspects that make photorealism viable at the city scale:

- Level of detail. Models load finer geometry only when the camera approaches, saving memory.

- Streaming assets. Textures and meshes arrive in manageable chunks rather than overwhelming the system.

- Lighting consistency. Global illumination techniques ensure accuracy across both interior and exterior spaces.

As a result, you've got an experience that convinces the eye while still maintaining responsive interaction.

Direct Use of BIM and CAD Data

Engineering models once had to be broken down or simplified before use in real-time engines. Unreal Engine changes that process by accepting BIM and CAD formats directly, which undoubtedly removes repetitive conversion steps and keeps critical metadata intact. Teams no longer lose information about materials, dimensions, or structural properties during the visualization process.

A digital twin that retains BIM attributes lets users do more than admire geometry. They can query components, highlight systems, or filter layers by discipline. Therefore, preserving this data reduces misunderstandings between design and construction teams.

Essential improvements that stand out in practice include:

- Native import. Plugins enable the import of IFC, DWG, and Revit files into projects with minimal preparation.

- Data integrity. Parameters such as fire ratings, materials, or load values remain attached to objects.

- Cross-discipline clarity. Architects, engineers, and contractors can all reference the same enriched model without manual mapping.

The process accelerates collaboration and ensures that every party works with a consistent source of truth.

Simulations that Go Beyond Visualization

Unreal Engine extends digital twins far beyond passive viewing. Its physics systems, lighting tools, and interaction models enable stakeholders to test how a project will behave in real-world conditions before construction or deployment begins. As our experts point out, this interactive layer often becomes the turning point where a digital twin shifts from being impressive to being indispensable.

- Construction phasing. Crews, cranes, and material deliveries can be arranged in different sequences to identify bottlenecks or safety risks. Testing these scenarios virtually means fewer delays and clearer site logistics when work begins.

- Operational logistics. Passenger flow through airports, cargo handling at ports, or warehouse automation can be modeled in detail. Adjustments to layout or staffing levels show immediate effects, helping managers choose the most efficient configuration.

- Emergency response. Evacuation drills, fire containment strategies, or natural disaster scenarios can be run safely inside the twin. First responders can practice routes, decision points, and timing without real-world danger.

- Traffic and mobility. Vehicle movement, signaling changes, and pedestrian interactions are simulated at scale. Planners can test new intersections or public transit routes and measure their impact before committing funds.

Ultimately, managers leave meetings with tested scenarios, validated safety measures, and concrete numbers, rather than assumptions. That balance of realism and foresight defines why Unreal Engine simulations carry lasting value for critical infrastructure projects.

Where Twinmotion Adds Value

Twinmotion supports projects that need speed and clarity rather than full simulation depth. It allows design teams to create high-quality visuals quickly, helping clients understand concepts without waiting for complex setups. The platform includes an extensive library of ready-to-use assets, such as realistic vegetation, dynamic characters, and environmental effects, significantly accelerating the visualization process. Based on our experience, Twinmotion is often the bridge between early design discussions and more advanced Unreal Engine workflows.

Fast Prototyping and Client Communication

Clients often need to see progress fast, even before detailed modeling is complete. Twinmotion is designed for that type of rapid delivery, giving design teams a way to turn concepts into clear presentations on short notice.

When used in early discussions, it enables:

- Rapid iteration. Design choices can be altered during meetings, allowing clients to compare options without delay.

- Visual clarity. The photorealistic look, combined with simple controls, ensures even non-technical audiences follow the proposal.

- Engagement. Interactive features such as VR preview and animated weather help clients ask informed questions.

Our team members reveal that providing early clarity reduces costly misunderstandings once projects move into construction or manufacturing.

Bringing Geospatial Context into Twinmotion

Showing a design in its proper location makes presentations far more convincing. While Twinmotion does not directly stream Cesium development data, teams often export context as glTF models and import them for review sessions.

Applied effectively, this approach supports:

- Site awareness. Authentic terrain and nearby buildings give viewers a sense of scale and orientation.

- Design validation. Real surroundings highlight how sunlight, sightlines, and accessibility align with the concept.

- Stakeholder trust. Clients respond better when they see proposals set within the actual neighborhood.

Therefore, even approximate context improves the quality of client feedback because people judge a proposal relative to its environment.

Migrating to Unreal with Datasmith

Projects that begin in Twinmotion often grow beyond simple visualization. As design complexity increases, they require deeper simulation, data integration, and interactivity. Datasmith makes this transition smooth by carrying assets, materials, and lighting setups directly into Unreal Engine. Nothing needs to be rebuilt from scratch, which means early work in Twinmotion remains valuable as the project scales. The ability to preserve both geometry and scene structure shortens timelines and protects the investment of effort spent during the first stages.

Once a project enters the Unreal Engine development, entirely new possibilities open up. IoT feeds can stream live data into the environment, Cesium can provide accurate geospatial context, and physics simulations can be layered into the scene. In our professional work, we have found that this workflow creates a practical path: quick visual results for client presentations at the start, followed by advanced, real-time digital twins later. Datasmith becomes the link that balances early speed with long-term depth, ensuring that design ideas evolve naturally into full-scale immersive platforms.

The Real Benefits of Combining Cesium and Unreal

When Cesium's geospatial backbone merges with Unreal's visualization strength, the outcome is more than the sum of its parts. Together, they deliver environments that scale smoothly, shorten production cycles, and secure sensitive project data. In our experience, this pairing consistently turns scattered information into a single, usable system that stakeholders can trust.

Scalability from Global Views to Local Details

A digital twin must handle both the big picture and the smallest element. Cesium streams vast terrain datasets, while Unreal renders them with precision. The combination allows users to zoom out to view a national grid and then zoom back in to inspect a single turbine or bridge joint without compromising performance.

To highlight how this plays out in practice:

- Continents. Wide-area overviews support regional planning for transportation or utilities.

- Cities. Urban twins enable zoning studies, shadow analysis, and crowd movement simulations.

- Sites. Detailed inspections of buildings, tunnels, or runways can happen without switching tools.

Notably, we've noticed that frame rates remain stable even as projects span multiple scales, proving that scalability no longer requires trade-offs.

Faster Development Cycles with Less Manual Work

Building large 3D environments traditionally involved weeks of manual cleanup, model conversion, and data stitching. Cesium and Unreal streamline that process by accepting a wide range of inputs and handling them efficiently. From projects we delivered, it became clear that developers spend far less time preparing data and more time refining outcomes.

A different way to view the benefit is through the sequence of project milestones:

- Import. BIM, CAD, and point clouds move directly into the pipeline.

- Stream. Cesium handles tiling and delivery, so assets load only when needed.

- Visualize. Unreal renders with lighting, physics, and interactivity intact.

- Iterate. Designers make changes quickly, testing them in minutes rather than days.

Measured improvements illustrate that timelines often shrink by 30–40 %, which frees resources for higher-value tasks such as simulation or optimization.

Secure and Controlled Data Sharing

Complex projects often involve confidential information. Design files, engineering models, and operational data cannot be distributed loosely. The Cesium–Unreal pairing addresses this with runtime streaming, meaning sensitive content stays on secure servers and is delivered only to authorized viewers.

Instead of a list, it helps to imagine how security unfolds across three layers. The first is access control, where user roles define precisely who has access to which assets. The second is data flow, since streaming prevents uncontrolled duplication of large files. The third is auditability, because logging functions create a record of who accessed data and when. Each layer contributes to maintaining trust without limiting collaboration.

Partner feedback demonstrates that this approach reassures both regulators and stakeholders. Engineers, planners, and investors all work from the same current model, while owners remain confident that intellectual property is not exposed. Security becomes an integral part of the workflow, rather than an afterthought.

Practical Scenarios Where Digital Twins Deliver Value

Digital twins are most persuasive when tied to concrete results. Real-world projects demonstrate how they reduce costs, enhance safety, and facilitate faster approvals. The strongest impact appears when teams use them not as static visuals but as decision platforms, where every choice can be tested in a lifelike environment before being implemented.

AEC and Infrastructure Planning

Architecture and construction benefit from context-rich models. Combining design files with geospatial layers, project teams catch problems that drawings alone would never reveal. Imagine validating a high-rise against terrain slopes, shadow impacts, or flood risks before a shovel hits the ground.

Key uses include:

- Design validation. Structures can be checked against environmental factors such as wind, light, or soil conditions.

- Clash detection. BIM elements from multiple contractors merge in one space, exposing conflicts early.

- Stakeholder alignment. Investors and city officials tend to understand proposals more easily when they are presented in a 3D context.

Our methodology ensures that design reviews become more than formalities. They become workshops where everyone views the same data, and measurable insights back decisions.

Transportation and Mobility Networks

Efficient transport depends on how well different systems interact. A digital twin provides a single space to model roads, rail, ports, and even pedestrian flows. By layering operational data, planners gain visibility into choke points long before they create real congestion.

The benefits stand out clearly when compared side by side:

- Without twins. Traffic simulations run separately for each mode, data is siloed, and adjustments take weeks.

- With twins. All networks merge, live sensors feed conditions, and planners test reroutes in minutes.

Measured improvements illustrate shorter delays in urban transit projects and higher throughput in cargo terminals. As confirmed by our clients, transparency across departments also improves because every team works on the same synchronized model.

Defense, Security, and Training Environments

Digital twins built on Cesium and Unreal provide accurate terrains, infrastructure replicas, and interactive scenarios where teams can prepare for complex missions. Cesium's technology efficiently streams real-world, global-scale geospatial data into Unreal Engine's visualization environment.

Practical applications include emergency drills, force deployment exercises, and infrastructure protection planning. Units can practice evacuation paths, measure the timing of coordinated responses, and test the resilience of assets under simulated threats.

Unlike generic simulators, these environments mirror the actual ground, so training outcomes directly transfer to the field. As we work on more similar projects, it has become clear that integrating live sensor feeds with the model also enhances situational awareness during operations. Decision-makers rely on the twin not just for preparation but also for real-time monitoring and response coordination.

Getting Started with an Immersive Digital Twin

Teams need clarity on why they are building it, which data sources will support it, and which platform will make the model practical. Projects that invest effort in these early decisions avoid later setbacks and achieve faster, more reliable results.

Setting Clear Goals and Success Criteria

A digital twin can serve multiple purposes, including design review, operational monitoring, predictive maintenance, and training. Without defined goals, projects risk spreading effort too thin. Setting objectives early creates a framework for measurement and accountability.

Successful projects usually define:

- Primary purpose. Is the twin meant for construction validation, ongoing operations, or risk training?

- Performance metrics. Which KPIs will signal value — reduced rework, faster approvals, or fewer incidents?

- User roles. Who needs access — managers, engineers, or external stakeholders?

Our expertise shows that projects with clear targets deliver results that can be measured, reported, and scaled. Goals convert a digital twin from an interesting model into a tool that justifies investment.

Choosing and Preparing the Right Data

Even the most advanced platform cannot add value if the source data is of poor quality. Digital twins rely on combining BIM files, geospatial layers, IoT streams, and, in some cases, photogrammetry. Preparing this data carefully avoids inconsistencies later.

Practical steps often include cleaning BIM models, normalizing coordinate systems, and filtering point clouds to manageable sizes. The geospatial context should match the project scale: national coverage for utilities or highly detailed terrain for a single building site. IoT feeds also require attention, as noisy or unstructured signals can slow down the system.

Early investment in data preparation saves both time and money in the long run. When models are aligned from the outset, the digital twin operates more smoothly and gains the trust of stakeholders.

Picking the Best Runtime for the Project

Not all digital twins need the same runtime. Unreal Engine offers depth for real-time interaction, Twinmotion speeds up concept reviews, and web deployment ensures broad accessibility. Choosing the right environment depends on the audience, the project's complexity, and its specific plans.

Narrative examples clarify the differences. A city planning session might use Twinmotion to present options quickly to officials, then migrate the project into Unreal for detailed simulations. A utility company could deploy a web twin, allowing field teams to access live asset data on tablets. A defense training scenario benefits most from Unreal, where physics and terrain accuracy matter.

Finally, aligning the runtime with the project's maturity stage enables organizations to control costs while still allowing for growth. The right choice prevents overengineering while keeping the path open for expansion.

Program-Ace Expertise and Certification

Program-Ace is a Certified Cesium Developer with proven experience in building digital twins, geospatial platforms, and enterprise-ready solutions. Our work spans industries, including construction, energy, defense, and telecommunications, with a focus on scale, precision, and integration. From our experience, certification is not just a credential but a confirmation that our solutions meet demanding enterprise standards worldwide.

Certified Cesium Developer Advantage

Becoming a Certified Cesium Developer signals verified proficiency with CesiumJS, Cesium ion, and 3D Tiles. Program-Ace engineers apply these tools to projects ranging from global monitoring platforms to city-scale digital twins. Certification assures clients that we follow the best practices in performance, interoperability, and geospatial accuracy. Partner feedback demonstrates that this validation reduces risk, accelerates procurement, and fosters confidence that projects will meet both technical and strategic objectives.

Performance Optimization for Large-Scale Projects

Our engineers focus on refining Cesium streaming pipelines by adjusting tile loading and optimizing assets to maintain stable frame rates, even in scenes with billions of polygons. Such improvements lower bandwidth demands while preserving detail. Users can seamlessly transition from wide-area views to close inspections without experiencing performance issues. Whether you need digital twins in construction or any other industry, Program-Ace adapts its solutions to fit specific objectives, data sources, and workflows.

Cross-Platform Deployment for Web, Mobile, Desktop

Enterprises often require tools that function across different environments. Program-Ace develops Cesium applications that run reliably on web browsers, mobile devices, and desktop systems. Integration with Unreal adds realistic visuals, while AI and IoT connections provide predictive insight and live operational data. Our experience shows that consistent performance across platforms not only expands availability but also strengthens user confidence in the system. Each deployment is tailored to the workflows it must support, ensuring that users derive value without added complexity.

Smart City Success: Program-Ace Urban Digital Twins

Program-Ace transformed fragmented geospatial information into interactive 3D digital twins. Now, environmental agencies and planners see one dynamic picture of their cities. Want to understand how?

Program-Ace as Your Partner in Digital Twin Development

Program-Ace is a Certified Cesium Developer with years of proven practice in building advanced digital twin solutions. We design platforms that integrate Cesium with Unreal Engine, AI, IoT, and Computer Vision, enabling accurate geospatial streaming and photorealistic visualization in one seamless workflow. Our team supports industries as diverse as construction, energy, defense, telecommunications, and logistics, constantly adapting to sector-specific requirements.

Every project is approached with attention to scale, accuracy, and integration into existing enterprise systems. Whether the goal is a city-scale twin, an enterprise monitoring platform, or a training simulator, Program-Ace provides both technical depth and practical delivery. Innovative solutions integrator isn't just a phrase, as it reflects how we connect cutting-edge technology with real-world needs.

Contact us to discuss how our Cesium expertise and multi-technology approach can transform your data into operational, measurable results.