It’s no secret that modern-day manufacturers are willing to go to any lengths to improve production efficiency and boost profit. This desire has caused many businesses to embrace cutting-edge solutions like PLM, robotics, and AI/ML. Each of these solutions is great in its own right, but there is one more that we should pay attention to — configurators.

A manufacturing product configurator is a digital solution that lets manufacturers customize various aspects of an item’s production and further lifespan. Typically, it includes 3D visualizations of the product, production line, etc., as well as realistic visual changes when custom options are applied.

Toyota, Peugeot, Nike, and Ikea are just a few of the hundreds of firms that have embraced this solution, and when you see what manufacturing configurators can do for your business, your company might join this list. In this article, we will give you all the details about choosing the right custom product configurator software for your business.

Looking for qualified help with manufacturing product configurator development?

What Is a Product Configurator?

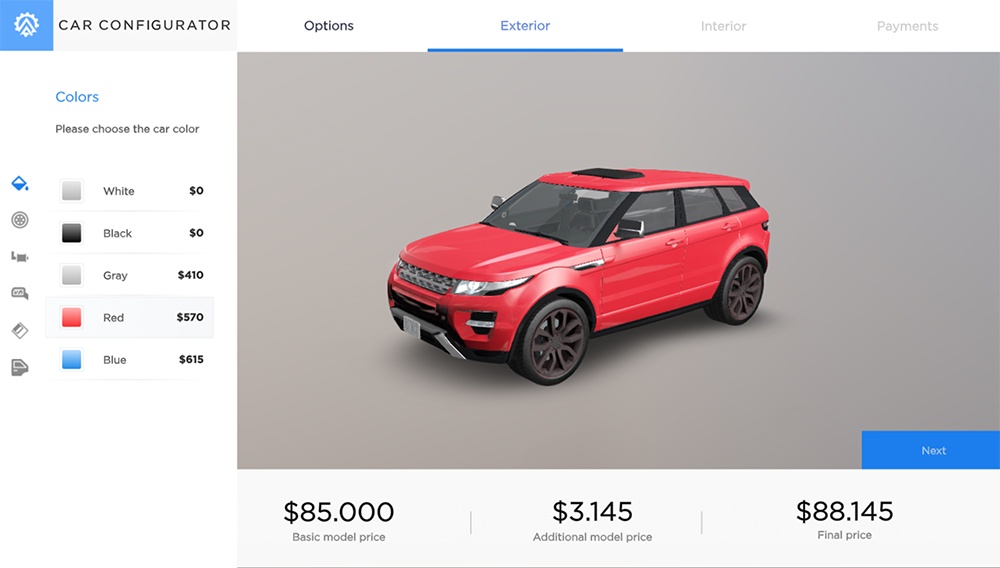

A product configurator is a digital tool that allows users to customize products according to their preferences and needs. These configurators are widely used in industries like automotive, furniture, and fashion, enabling customers to select various features, colors, materials, and other options. By offering an interactive and visual experience, configurators empower users to see their customized product in real time before making a purchase.

In the automotive industry, for example, a product configurator allows users to choose the model, color, interior design, and additional features like sunroofs or upgraded sound systems. In the furniture sector, it enables the selection of fabric types, colors, and specific dimensions, helping customers create furniture pieces that fit perfectly in their spaces. Fashion brands use configurators to let customers design their own shoes, clothing, or accessories, selecting everything from materials to monogramming options.

Product configurators enhance the customer experience by providing a sense of control and personalization. They reduce the gap between customer expectations and the final product, minimizing the chances of dissatisfaction. For businesses, configurators can streamline the sales process, reduce return rates, and increase customer engagement.

The integration of advanced technologies like augmented reality (AR) further elevates the functionality of product configurators. AR allows users to visualize their customized products in their actual environment, enhancing the decision-making process. By incorporating these digital tools, businesses can offer a more interactive and satisfying shopping experience, ultimately driving higher sales and customer loyalty.

Benefits of Implementing a Manufacturing Product Configurator

Implementing a manufacturing product configurator offers numerous benefits, driving both operational efficiency and customer satisfaction. Understanding these benefits can help you make an informed decision about integrating this tool into your production process.

-

Increased efficiency. Automating the customization process reduces manual labor and the likelihood of errors, speeding up production timelines and improving overall workflow.

-

Cost savings. By minimizing errors and material waste, configurators can lead to significant cost reductions. Accurate configurations prevent costly rework and ensure optimal use of resources.

-

Enhanced customer experience. A user-friendly interface and real-time visualization make it easier for customers to customize products to their specifications, leading to higher satisfaction and repeat business.

-

Shorter lead times. Streamlined customization and production processes result in faster delivery times, meeting customer expectations, and increasing competitiveness.

-

Scalability. Configurators can quickly scale with your business, accommodating an expanding product line and increasing order volumes without sacrificing accuracy or efficiency.

-

Data insights. Configurators generate valuable data on customer preferences and trends, allowing you to refine your product offerings and marketing strategies based on real-time feedback.

-

Flexibility. Easily update and modify product options and configurations to reflect changes in market demand or new product introductions, keeping your offerings current and competitive.

-

Competitive advantage. Offering a high degree of customization can set your business apart from competitors, attracting customers looking for personalized solutions.

-

Reduced returns. Accurate configurations ensure that customers receive exactly what they ordered, reducing the likelihood of returns and exchanges and improving overall satisfaction.

-

Brand loyalty. A seamless and satisfying customization experience fosters brand loyalty, encouraging customers to return for future purchases and recommend your business to others.

By leveraging these benefits, a manufacturing product configurator can significantly improve your production processes, enhance customer satisfaction, and drive business growth.

What Types of Manufacturing Product Configurators Can You Choose?

Contrary to what some people think, configurator solutions are not a monolith and do not all function the same. Thus, you can see many different versions used in manufacturing and choose the kind that best works for you. Let’s examine some of the most common types:

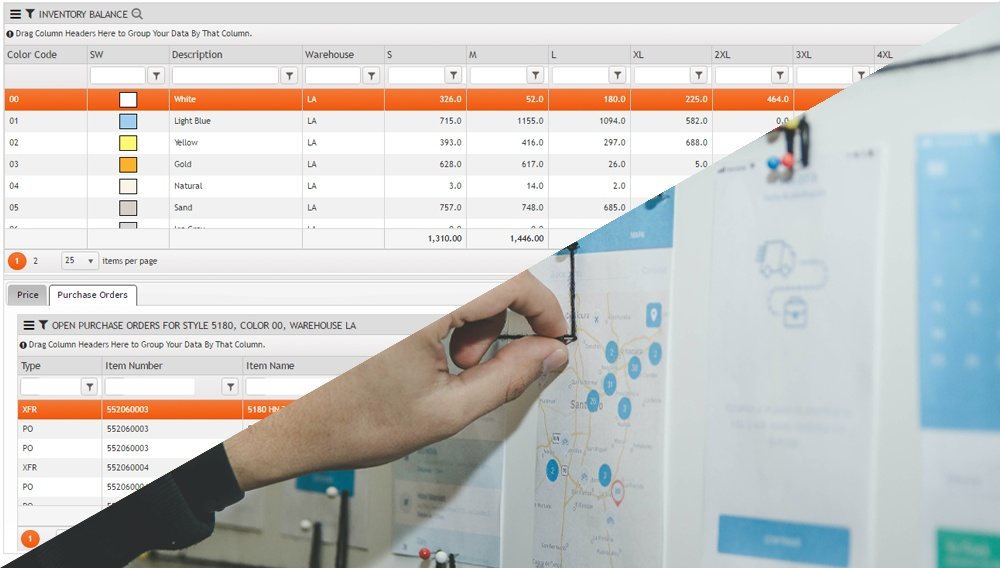

1. ERP/MRP product configurator

Enterprise resource planning (ERP) and material resource planning (MRP) are two common approaches for digital transformation in manufacturing. They aim to unite all core business processes (including management of materials) under a single software platform, where global changes can be easily applied with real-life repercussions.

Accordingly, configurators of this type can be used to test or apply changes to company processes. To illustrate, a typical interface of such a configurator might contain options to increase/lower the volume of raw materials shipped in, with the application then calculating further changes that should be made to effectively process the materials.

Example: C&C Power, Inc

The experts over at C&C Power, Inc are prominent energy equipment manufacturers based in the U.S. The company faced serious delays in order fulfillment that stretched up to 60 days until they integrated a new configurator. This new solution has helped them modify orders on the go and better regulate the flow of materials. The software also identifies problems and bottlenecks in production, making relevant suggestions to improve them.

Benefits:

- Faster logistics flow

- Conservation of time & materials

- Very precise production results

- Quick reorganization after changes

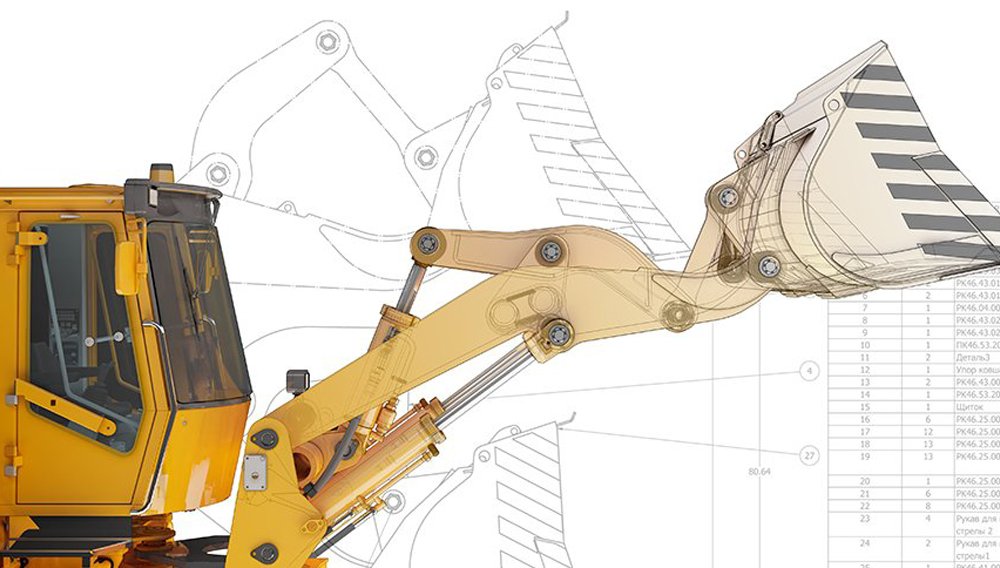

2. CAD product configurator

This solution is used predominantly during product development, and makes use of CAD (computer-aided design) software, which is usually built into the configurator application. Because of the vital design features that make rapid prototyping possible, this tends to be a 3D product configurator with a high-detail visualization of the product and dozens of options to modify its parts. It may carry additional functionality to update the product’s performance specs in sync with design changes.

Example: CAMotion

This company produces palletizing machinery and robot systems, and they chose to implement a configurator after determining that a lot of time was being wasted on creating CAD parts for custom product designs. Their configurator (which consisted of many tools used together) greatly simplified CAD and shortened the time-to-production from 4 weeks to 10 days.

Benefits:

- Designs are completed faster

- Automation reduces human error

- Failed prototypes minimally impact development

3. Training product configurator

As the name implies, a training configurator is intended for learning about the product. Usually, it is provided to sales associates, engineers, and other technical staff that must have good knowledge of the product. The solution can visualize the product and let the user examine/tinker with its parts. This helps them learn where everything is located and how the product works.

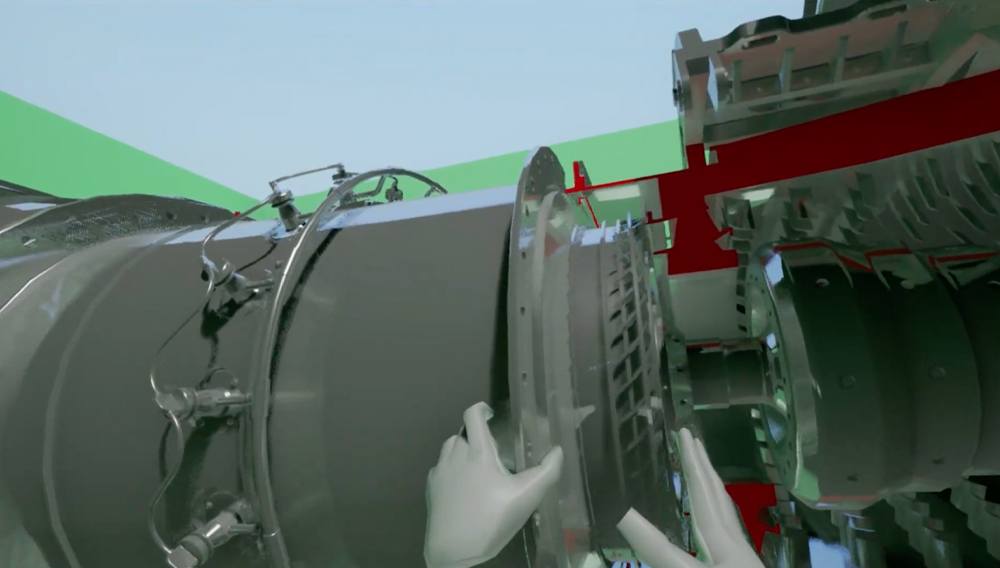

Example: Aircraft Engine VR Training

This solution was built by Program-Ace and features an interactive 3D model of a popular aircraft engine model. We designed it to be used in virtual reality, so users put on a headset and controllers, launch the software, and are transported to a virtual training room. There, they can assemble and disassemble all of the parts of the engine at a leisurely pace, placing the individual parts on the ground or hanging in the air.

Benefits:

- Higher engagement in training

- No real product equipment necessary for testing

- Realistic and cost-free learning

- Learning can happen anywhere and anytime

4. BOM product configurator

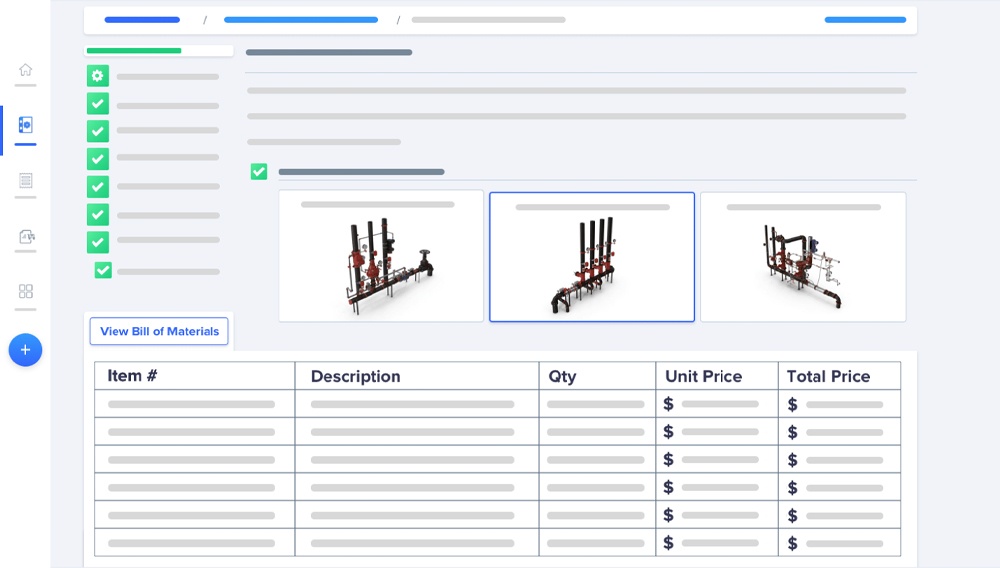

A BOM configurator is a very narrow-use solution intended for the quick creation of a Bill of Materials (BOM). The bill of materials is a document containing all the details about the materials, parts, components, and other dynamic resources needed to manufacture a product.

Accordingly, the configurator that generates this document allows the user to modify certain values and see instant changes in other values included in the document. The changes can be applied in a limited scope (for example, for a single-day shipment of materials) or apply to the whole business model.

Example: CEVT

CEVT is the company responsible for building the massive design platform used by Volvo in the production of its vehicles. The tool they helped build and integrated into their business processes turned out to be a game-changer. It replaced all the other instruments they were using in the pre-production stages and even saw lowered costs due to effective material planning.

Benefits:

- Fewer materials wasted

- Faster pre-production

- Reduced design costs

- High usability

5. CPQ product configurator

CPQ configurators are often associated with eCommerce and retail, so what do they have to do with manufacturing? Well, we should never forget that many manufacturing companies rely on other businesses to sell their product. Thus, product configurators for make-to-order manufacturing help their clients choose the most suitable version of the product that they are ready to sell. CPQ stands for “configure — price - quote” — the uninterrupted process of choosing and buying a product online.

Example: Motorola

Besides making mobile phones, Motorola is also a major manufacturer of security hardware. Through a state-of-the-art CPQ configurator, they let businesses choose a security system tailored to their needs. The software features over 1000 possible product builds and has sped up the sales/consultation in a big way.

Benefits:

- More attractive to customers

- Sales work is made simpler

- Increased customer traffic

- Easier organization of orders

Still not sure what to choose? No problem

The list above is hardly exhaustive, and does not cover all the purposes and functionality that can be delivered with configurators. Similarly, there are many more benefits of product configurators worth mentioning. Thus, you can easily opt for a hybrid configurator combining several of the listed functions or go in a totally different direction with a custom configurator.

Which Additional Features Can You Add to Your Manufacturing Configurator?

If you go the custom route and build a configurator from scratch, you will have a lot of freedom in adding the features and functionality you want/need. Below are some of the most popular choices:

-

Immersion

If you build an AR product configurator or one based on virtual reality, you can make any interactions with the product much more engaging and informative.

-

Animation

In addition to showing off your product’s look, you can also demonstrate how it functions through high-detail and realistic animations.

-

Save/export of configuration

A “save” option built into your software can allow users to print and reuse designs/builds, as well as return to configuration when they reopen the file.

-

Universal accessibility

Making a web-based product configurator is one of the best choices you can make to increase its accessibility, since most devices with a web browser will be able to open it.

-

Support button

Whether your configurator is meant for internal or commercial purposes, adding an option to contact support can be helpful in fixing issues with the software or helping users make informed choices with the app.

You can also explore types of product configurators to understand where manufacturing-focused solutions fit within the broader classification.

What to Consider When Selecting a Product Configurator

When selecting a product configurator, consider several crucial factors to ensure it meets your business needs and enhances the customer experience. A well-chosen configurator can significantly impact user satisfaction and sales. Here are key aspects to evaluate:

User interface. The configurator should have an intuitive and user-friendly interface that allows customers to navigate and make selections without confusion.

Customization options. Ensure the configurator offers various customization options that are relevant to your products. This includes choices in color, material, size, and additional features.

Real-time visualization. A configurator that provides real-time visualization helps customers see changes instantly as they customize the product, enhancing their confidence in their choices.

Integration capabilities. Check if the configurator can seamlessly integrate with your existing systems, such as e-commerce platforms, CRM, and inventory management systems, to streamline operations and maintain data consistency.

Mobile compatibility. With increasing mobile shopping trends, the configurator must be mobile-friendly and offer a smooth experience across all devices.

Performance and speed. A slow or lagging configurator can frustrate users and lead to abandoned sessions. Ensure the tool performs well under high traffic and complex customizations.

Security features. Protecting customer data is paramount. Ensure the configurator adheres to the latest security standards and practices, including data encryption and secure payment processing.

Support and updates. Choose a provider that offers reliable support and regular updates to keep the configurator running smoothly and securely.

Cost-effectiveness. Evaluate the pricing model to ensure it aligns with your budget while providing the necessary features and scalability.

By thoroughly assessing these factors, you can select a product configurator that not only meets your business requirements but also enhances the overall customer experience, driving satisfaction and sales growth.

How Your Manufacturing Product Configurator Affects Customer Satisfaction

A manufacturing product configurator directly impacts customer satisfaction by enhancing the customization experience, improving accuracy, and reducing lead times. Here's how:

Empowerment. Allowing customers to personalize products gives them a sense of control, leading to increased satisfaction. They can select specific features, materials, and dimensions that suit their needs.

Transparency. Real-time visualization of product customizations ensures customers know exactly what they are getting, reducing uncertainties and boosting confidence in their purchase decisions.

Accuracy. Configurators help eliminate errors in orders by ensuring that all selected options are compatible and feasible for production. This reduces the chances of misunderstandings and dissatisfaction with the final product.

Efficiency. Speeding up the customization process, configurators enable quicker decision-making and shorten the overall purchase journey. Customers appreciate a streamlined and efficient experience.

Cost clarity. Displaying pricing updates in real-time as customers make choices helps them stay within budget and understand the cost implications of their selections. Clear pricing information enhances trust and satisfaction.

Support. Integrating help options, such as FAQs or live chat, within the configurator ensures customers can get assistance when needed, improving their overall experience and reducing frustration.

Consistency. Providing a consistent and reliable customization process ensures customers have a positive experience every time, fostering loyalty and repeat business.

Feedback integration. Collecting customer feedback through the configurator allows for continuous improvement of the tool, ensuring it evolves to meet customer expectations and preferences.

By focusing on these aspects, a manufacturing product configurator can significantly enhance customer satisfaction, leading to increased loyalty, positive reviews, and higher sales.

Maximize potential with product configurator solutions.

Where to Order a Manufacturing Product Configurator

If you look online, you can find a few ready-built enterprise configurators that are typically offered on a subscription basis. However, you should keep in mind that those solutions won’t be adapted to your business processes as well as a custom-built configurator. Ready-built configurators tend to have very limited options for personalization and 3D visualization, whereas custom software is made according to your precise requirements.

One of the providers that you can rely on for a custom product configurator is Program-Ace. Our company has been building solutions for the manufacturing industry for over a decade, and we can confidently say that product configurators are one of our biggest strengths. Seems like a match made in heaven, right?

If you have a configurator project in mind, feel free to read more about us, and send us a message to learn more about our services and cooperation.