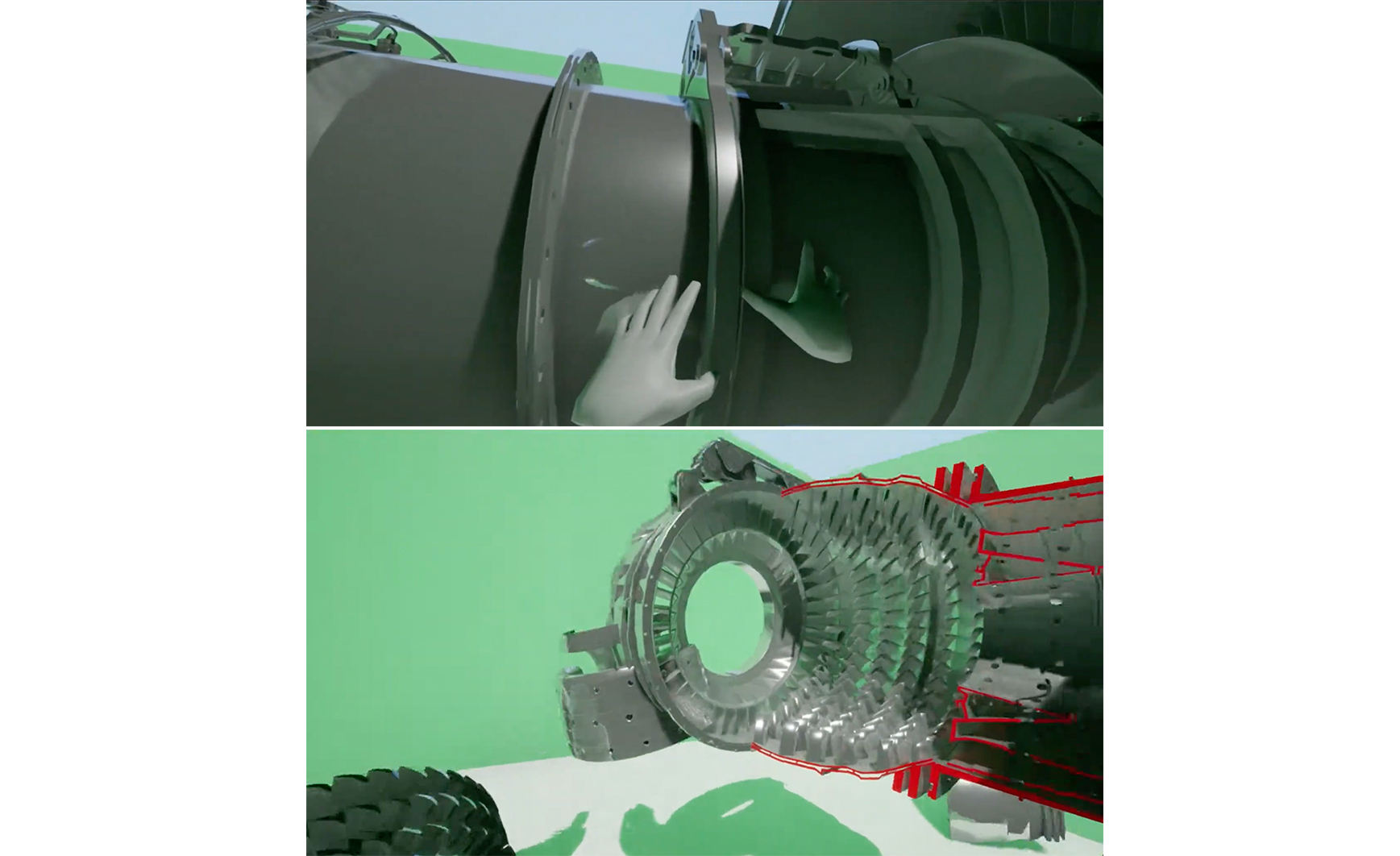

Our team successfully created a VR training experience that provides users with the opportunity to easily and effectively learn new technologies (VR and airplane engine assembly). They do not need to travel to an airbase or actually lift any engine parts, and can get all of the relevant information with just our software and the right headset. In fact, the interactive options built into the application offer even more freedom of movement and interaction than they would get from a real and physical program.

If you choose to integrate this solution (or another like it from Program-Ace) into your business, you can be prepared to gain several weighty advantages: