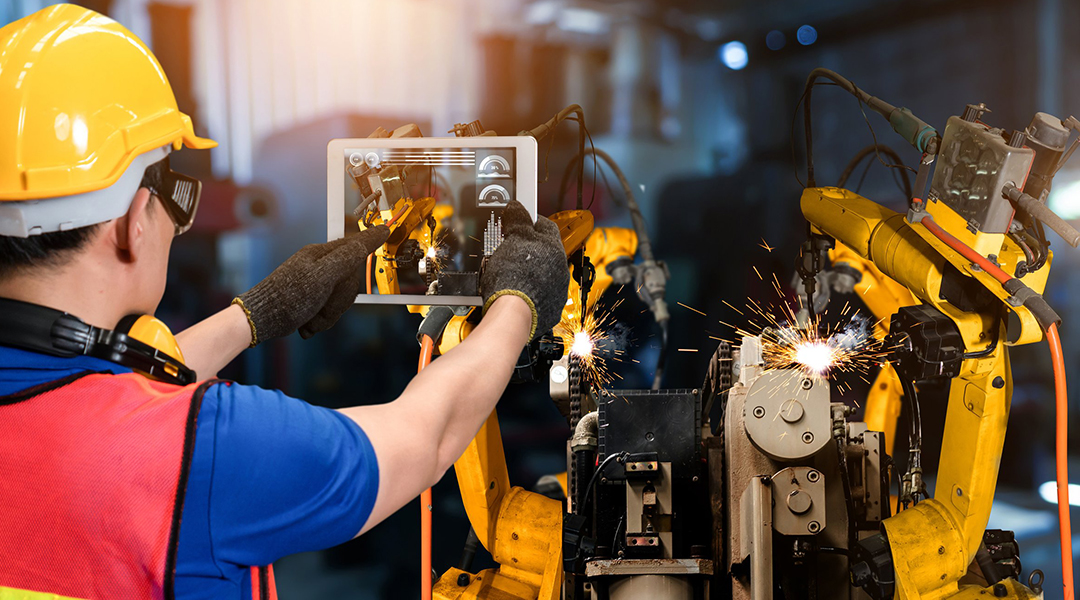

Manufacturing

Use manufacturing software solutions to train faster, reduce downtime, and improve your facility's performance. Choose from a suite of our ready-made solutions or ask us to build something that fits your production process.

Let’s discuss your projectYou deal with complex machinery, strict safety rules, and non-stop pressure to deliver. Program-Ace can help you build software that supports each step, training workers through simulation, running product configurators on the assembly floor, tracking asset performance with digital twins, or connecting your systems with virtual assistants that respond in real time. Every program we build reflects the pace and pressure of real factories.

You don’t have to throw out what already works. Our manufacturing software solutions connect with the systems you use now, whether MES, ERP, SCADA, or something built in-house. You can start small, like rolling out VR training for safety drills or building a 3D model of one machine. Later, scale to multiple lines, full production areas, or cross-plant operations. We support everything from concept to development, including R&D, business analysis, and integration.

Market Challenges Our Software Solutions Help Solve

What We Do for the Logistics Industry

Manufacturing Ready-to-Use Solutions

All SolutionsGet in touch to explore software solutions that help your team train faster, reduce unplanned stops, and run production with fewer delays.

Our Partners

Why Choose Us for Logistics Software Development

We build manufacturing software with a clear understanding of how production floors operate, so every solution fits into existing routines without slowing down tasks, shifting responsibilities, or introducing unnecessary complexity.

You get systems that follow the structure of your process from day one, which means your team keeps working the way they already know while gaining better visibility, control, and speed across operations.

Software is tested under conditions that match real manufacturing use, such as variable temperatures, loud machines, and inconsistent connectivity, so it keeps running when tight schedules and stakes are high.

Our developers and analysts stay involved from planning to rollout, so you always work with people who understand your goals, answer quickly, and stay focused on solving the right problems.

FAQ

Yes, our manufacturing software solutions can fully integrate with MES, ERP, and SCADA systems currently used across the manufacturing industry. We treat interoperability as critical to any implementation effort, especially when multiple systems handle operations, planning, and data acquisition. Each integration is built around your existing infrastructure to avoid process interruptions and maintain data continuity.

Manufacturing environments often include legacy systems with inconsistent data formats or outdated APIs. To address that, we create secure middleware layers or direct API bridges that allow stable, bi-directional communication between your current stack and our solutions. Support for protocols like OPC UA, MQTT, and Modbus enables us to interface directly with industrial equipment, while REST and SOAP-based APIs provide access to enterprise systems.

Integration efforts are focused on measurable impact, not unnecessary complexity. That includes:

- Faster deployment. Software adapts to your systems instead of requiring full replacements.

- Reliable data flow. Information moves cleanly between machines, interfaces, and reporting layers.

- Less manual work. Staff no longer waste time re-entering data across disconnected platforms.

You also retain full control over access rights, audit trails, and system behavior. Each solution is built to accommodate multiple sites, distributed systems, and safety-critical tasks without exposing gaps in control logic or production oversight. Proper integration also supports the importance of safety in manufacturing industry settings, ensuring that monitoring, alarms, and decision points stay connected in real time. To explore how integration can support your current systems, reach out to our team.

Timelines for developing and deploying custom manufacturing software solutions vary based on what you need, how your facility runs, and which systems are already in place. For most companies in the manufacturing industry, the process takes between 3 and 6 months, but the exact number depends on how complex the requirements are and how many teams will use the software.

We begin by meeting with your team to understand your current setup: production flow, equipment, roles, and any pain points you face. That planning phase usually takes 2 to 4 weeks and helps us build a clear development roadmap before any code is written.

Once the plan is in place, development moves forward in focused stages. You'll see working modules early on so you can test features while we continue building.

We ensure updates don't interfere with daily work or safety-critical operations.

- Initial planning. A clear overview of how your process works and what software is needed to support it.

- Core buildout. Development of main features and user interfaces tailored to your team.

- System connection. Integration with MES, ERP, SCADA, or any plant-specific tools.

- Deployment. On-site testing, staff onboarding, and performance checks.

We account for health and safety in manufacturing industry environments at every step, especially when timing affects access to machines or key data. Contact our team to discuss a realistic timeline for your facility.

We build virtual training programs that help your team learn how to operate machines safely and correctly without putting production at risk. Each program is based on your actual equipment and routines, so the tasks people practice are the same ones they'll handle on the floor.

You can use our solutions to walk new hires through equipment setup, shutoffs, or troubleshooting steps before they touch a real machine. Experienced staff can also refresh their knowledge or train for process changes without pulling systems offline.

The training runs in VR or AR, depending on what works better for your space and hardware. Teams can repeat sessions as often as needed, either in a structured course or on demand.

Managers can follow along, track progress, and see who's ready to move on or who might need more time.

- Real environments. Simulations are based on your machines and plant layout.

- No interruptions. Training doesn't affect schedules, equipment availability, or shift coverage.

- Clear tracking. Progress is recorded so you know exactly where everyone stands.

You don't have to pause work to build skills or rely on outdated videos to explain tasks that require hands-on practice. If you're looking for a faster, safer way to get people confident with equipment and procedures, connect with us to see your training program.

Our manufacturing software solutions are built to solve practical, ongoing challenges that affect productivity, accuracy, and coordination across your operations. Each system is designed based on how your facility runs, so the tools address real bottlenecks, not just generic pain points.

If your team spends too much time entering the same data in multiple places, we help automate routine tasks and connect systems so information moves without delays or errors. When onboarding takes too long or safety procedures aren't retained, our simulation-based training programs give your staff hands-on experience in controlled digital environments. We support better planning through real-time equipment monitoring and process tracking for teams dealing with downtime or maintenance issues.

- Manual bottlenecks. We reduce repetitive data entry and disconnected workflows.

- Training gaps. Staff practice critical tasks without halting production or exposing equipment.

- Downtime planning. Equipment usage is tracked so you can act before problems grow.

- System coordination. MES, ERP, and SCADA platforms work together instead of in isolation.

Software is never one-size-fits-all in manufacturing. That's why everything we build starts with your process and scales as your needs change. Whether you're managing a single line or coordinating across multiple sites, reach out to our team to talk through where software can make the biggest difference.

You can absolutely start with a smaller rollout and grow the system over time. Many of our manufacturing clients begin by focusing on one facility, a single production line, or a specific workflow like training, equipment monitoring, or task management. That approach makes testing how the software fits into daily operations easier without overloading your team or interrupting your process.

At Program-Ace, we build every solution using a modular system architecture. You won't need to restructure anything as your goals expand. When your company is ready to scale, whether it's adding more features, connecting new machines, or expanding to additional locations, everything builds on what's already in place. You won't need to manage disconnected tools or patchwork systems just to meet new requirements.

Your team can scale at a pace that fits your plans, infrastructure, and internal resources. There's no need to force a full rollout before you're ready. We help you grow in a way that's coordinated, technically sound, and aligned with how your production already runs. Each added step keeps your workflows consistent, your data structure clean, and your people focused on operations, not software transition.

If you're thinking long-term but want to start with something manageable, our team is ready to work with you and map out a clear, step-by-step path forward. Reach out to us to talk through your timeline and goals.

Customer Testimonials: The Proof is in Their Words

Start A Project With Us

Tell us more about your business needs to help us serve you better. The more detailed information will allow us to route your inquiry to the most appropriate person in our team.

By sending this form you agree to our Privacy Policy. The information you provide will be added to our CRM system for further communication.

Headquarters:

Our Clients