The border between real and virtual worlds becomes thinner and thinner day after day. And while we are still far from a movie-like futuristic dream of existing in a full-fledged digital dimension, the metaverse currently offers us a set of new opportunities not only for entertainment purposes but for soaring business growth and virtual economy expansion.

When starting a conversation about metaverse usage for business, we need to also pay attention to the phenomena of digital twins, the technology that also has been gaining momentum during the last few years. But how are the metaverse and digital twin connected? Find out the answer and comprehend the value of such a connection through the experience of a top metaverse development company.

What Is a Digital Twin in Metaverse?

A digital twin in the metaverse refers to a virtual replica of a physical object, process, or system intricately designed to mimic its real-world counterpart with high fidelity. These digital counterparts are integral to the metaverse, offering a dynamic and interactive simulation, analysis, and optimization platform. Within the expansive and immersive environment of the metaverse, digital twins serve as critical tools, enabling users to engage with and manipulate complex systems in a controlled virtual space.

The convergence of digital twin and metaverse technologies is particularly transformative in industrial applications, where virtual replicas of machinery, infrastructure, and processes can be created and analyzed. This synergy allows for real-time monitoring, predictive maintenance, and scenario testing without the constraints of physical reality, leading to enhanced efficiency, reduced downtime, and informed decision-making.

Moreover, the integration of a digital twin in the metaverse facilitates collaborative endeavors across geographical boundaries, empowering teams to work together on virtual models from anywhere in the world. This collaborative aspect is revolutionizing design, training, and operational strategies, making digital twins in the metaverse indispensable assets in various sectors, including manufacturing, healthcare, urban planning, and beyond.

Digital Twin and Metaverse: How to Understand These Two Concepts?

Beginning with the foundational elements, the metaverse represents an intricate network of interconnected virtual environments where users can engage in the tangible world through avatars facilitated by virtual reality technologies. Numerous standalone platforms offer virtual reality experiences, yet the envisioned seamless interconnectivity is still in the developmental phase.

The metaverse, despite not yet reaching its idealized state, holds significant potential to generate tangible benefits for businesses. The array of metaverse use cases extends from providing immersive experiences for employees and customers to unlocking new avenues for revenue generation.

The metaverse has captured the attention of industry leaders across various sectors over the past few years, becoming a subject of keen interest. With significant technology corporations like Meta investing resources into the metaverse, its expansion and broader adoption across the global business landscape are anticipated.

Conversely, the digital twin concept predates the metaverse, having been introduced in the early 2000s and subsequently integrated into business operations. Organizations require robust technological infrastructure to fully leverage the advantages and competitive benefits offered by a digital twin, including enhanced connectivity, ample data storage capabilities, and sufficient bandwidth.

A digital twin creates a precise digital counterpart of a physical asset, process, or product, continuously updated with real-time data reflecting the original's status, environmental conditions, and other influencing factors. Digital twins serve various purposes, ranging from facilitating virtual training accessible around the clock to enabling predictive maintenance for industrial machinery and infrastructure.

The technological prerequisites for efficient digital twin operation may have been prohibitive for some businesses in the past. However, the advent of advanced technologies, notably the digital twin and metaverse integration, is rendering the adoption of digital twins more feasible and economically viable than ever before. This synergy between digital twins in the metaverse is paving the way for innovative applications, particularly in industrial contexts, where the fusion of digital twin and metaverse concepts are revolutionizing traditional practices.

Digital Twin vs. Metaverse: How Do They Relate?

Integrating digital twins within the metaverse framework unlocks unprecedented opportunities for metaverse development companies. The concept of the metaverse, often perceived as an autonomous virtual universe detached from our physical existence, holds the potential for incorporating highly accurate digital simulations of the real world. In this context, the role of digital twins is becoming increasingly indispensable. They facilitate the creation of precise digital replicas of tangible objects or processes, thereby enhancing the realism and applicability of virtual environments.

Digital twins serve as foundational elements in constructing the metaverse, enriching virtual experiences with a level of realism previously unattainable. This fusion of digital twin and metaverse technologies is exceptionally beneficial for the corporate sector. It transcends the limitations and hazards associated with physical operations, thereby unveiling vast new vistas for exploration and innovation.

Consider, for instance, the expertise offered by a seasoned digital twin development company. Such an entity is equipped to replicate your company's industrial setting virtually, enabling you to experiment with modifications in manufacturing workflows. This virtual testing ground allows for the collection and analysis of metadata to evaluate the potential impacts of these modifications on operational efficiency, safety, and the dynamics between machinery and personnel.

The synergy between the metaverse and digital twins facilitates the precise virtual modeling of scenarios, mirroring real-world outcomes without the associated interruptions to production or the risks of downtime. This approach eliminates the expenditure of resources on unverified hypotheses and mitigates the hazards to employee safety.

Through the strategic application of digital twins in metaverse technologies, businesses are empowered to conduct risk-free explorations and make informed decisions, thereby revolutionizing traditional industrial practices and setting a new standard for innovation in the digital era. The collaboration between digital twin and metaverse concepts is not just theoretical but a practical approach to pushing the boundaries of what is possible in both virtual and physical domains.

Benefits of Combining Digital Twin and the Metaverse

-

Enhanced realism. The fusion of digital twin technology with the metaverse provides a platform for constructing highly accurate and immersive virtual environments. This integration enables the creation of digital replicas that closely mirror the physical world, offering users a more compelling and immersive experience.

-

Innovative solutions. By harnessing the combined strengths of digital twin and metaverse technologies, metaverse development companies are positioned to pioneer solutions that transcend traditional boundaries. This collaboration facilitates the simulation of real-world scenarios within virtual spaces, offering a unique environment for testing and refining new ideas and innovations.

-

Operational efficiency. The strategic application of a digital twin in the metaverse, particularly within industrial contexts, can markedly enhance operational efficiency. Simulating industrial processes within the metaverse enables organizations to pinpoint inefficiencies and optimize operations prior to implementing changes in the tangible world.

-

Risk reduction. The integration of digital twins with metaverse technologies allows organizations to evaluate risks in a virtual setting, substantially reducing the potential for costly errors in the physical realm. This approach enhances safety and diminishes the likelihood of operational downtime.

-

Data-driven decisions. Collaborating with a digital twin development company enables businesses to base strategic decisions on robust data derived from digital twins in the metaverse. This data provides invaluable insights into performance, utilization patterns, and improvement opportunities.

-

Training and development. Digital twin and metaverse technologies offer an effective training and development tool. Employees can engage with digital replicas of machinery and processes within a risk-free virtual environment, enhancing their skills without the hazards associated with physical exercise.

-

Customer engagement. Demonstrating products, services, and processes through digital twins in the metaverse can significantly boost customer engagement and comprehension. This interactive method allows customers to explore and interact with digital replicas in a manner unachievable through conventional approaches, deepening customer connections and fostering brand loyalty.

Digital Twin in Metaverse: How Does It Work?

Integrating digital twins within the metaverse framework provides significant value by establishing a seamless connection with the natural world through continuous data exchange. This connectivity enables organizations to visualize their products and operational processes dynamically under varying conditions. This feature is particularly beneficial for complex products composed of numerous advanced components, where alterations in one element can significantly impact the overall performance and functionality of the product.

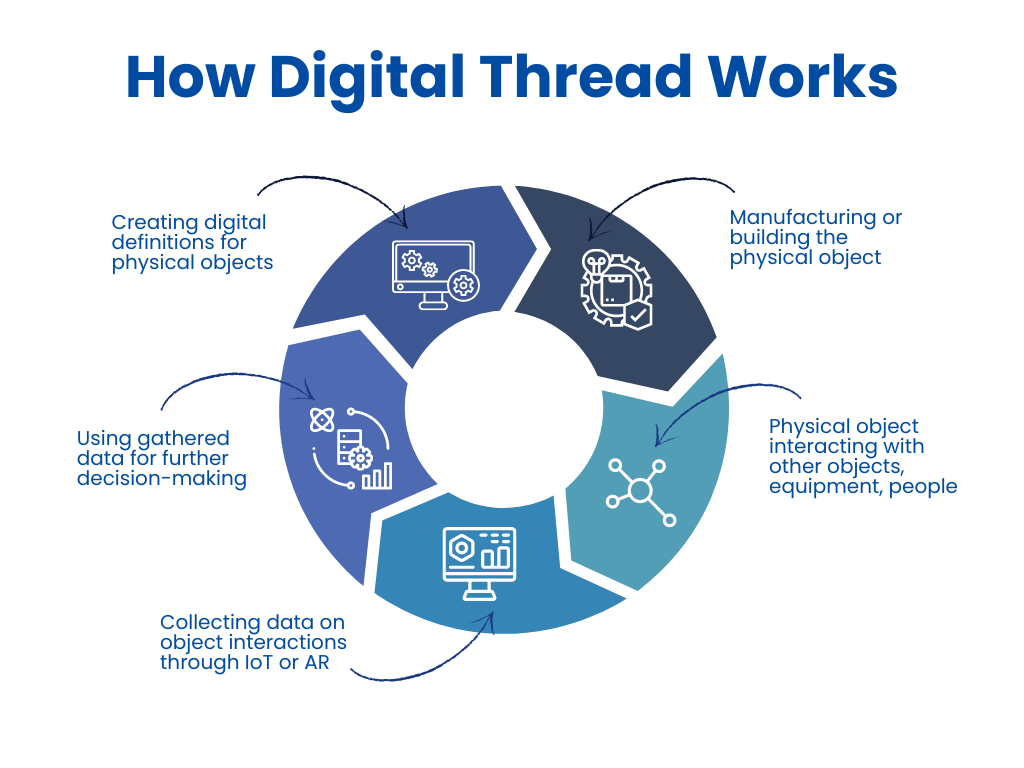

In the metaverse, employees gain enhanced capabilities to interact with, monitor, test, and analyze digital representations, broadening their work scope and improving efficiency. The concept of digital threads plays a pivotal role in this integration, ensuring a continuous flow of data between the digital and physical domains. This process begins with digital definitions, such as models and prototypes, which lay the groundwork for constructing the physical counterpart.

As products or installed equipment interact within their environment, encompassing other objects, individuals, and processes, technologies like augmented reality (AR) or the Internet of Things (IoT) become crucial. They enable the collection of data from these interactions, which can then be utilized for informed decision-making and enhancing operational processes. This cycle, encapsulated by the digital thread concept, completes a loop of continuous feedback and improvement.

When these digital threads are visualized using 2D or 3D modeling and synced with real-time data, they materialize into a digital twin. For businesses, understanding the three primary types of digital twins is essential:

- A product digital twin. This type represents a specific product, allowing businesses to simulate how the physical product will perform under diverse conditions or how changes in materials, hardware, or software could influence the product comprehensively.

- A production digital twin. Focused on operational processes, this twin facilitates digital testing and validation of processes before implementation, ensuring efficiency and reducing the risk of errors.

- A performance digital twin. This variant collects and analyzes data from assets in use, providing valuable insights into performance metrics that can inform further decision-making and strategic planning.

Nevertheless, these examples merely scratch the surface of the potential applications of digital twins. The spectrum of digital twins and their applicability is vast, allowing businesses to customize this technology to meet their needs. With the expertise of metaverse developers and specialists in digital twin and metaverse integration, companies have the opportunity to harness this technology's full potential.

Tailoring digital twin solutions, especially when combined with the immersive capabilities of the metaverse, enables organizations to innovate, optimize, and revolutionize their operations, particularly in industrial sectors where the fusion of digital twin in metaverse technologies can lead to groundbreaking advancements.

Find out how the metaverse digital twin can enhance your business processes.

How Can We Use Digital Twins in the Metaverse?

A digital twin in the metaverse is a high concept, but how do enterprises in different industries actually apply it?

1. Manufacturing

The industrial metaverse concept introduces an innovative dimension to the broader metaverse narrative, suggesting its potential to significantly impact society and the economy beyond sophisticated entertainment and retail scenarios. The fusion of the metaverse with Industry 4.0 principles, which heralds the convergence of advanced technological adoption and the blurring of lines between the physical, digital, and biological domains, is particularly noteworthy.

Entities within the manufacturing sector have long utilized digital twins, but the integration of these with the metaverse ushers in a novel virtual ecosystem aptly termed the "meta factory." This metafactory paradigm is characterized by its continuous operation and remote accessibility, facilitating unparalleled collaboration among experts from diverse fields on various projects, thereby dramatically reducing project timelines.

Traditionally, even with the implementation of digital twins, specialists would often have to physically travel to specific locations to conduct maintenance, inadvertently prolonging equipment downtime and only fully grasping the issue upon arrival. The metaverse, however, revolutionizes this approach by enabling specialists to assess and commence maintenance procedures virtually without needing physical presence.

Moreover, the immersive capabilities inherent to the metaverse enhance collaborative efforts, allowing teams to identify production anomalies or uncover avenues for optimization swiftly. This capability is instrumental in preempting process interruptions and mitigating equipment downtime. The metaverse developers play a pivotal role in crafting these immersive environments where digital twins operate, further blurring the distinctions between the virtual and physical. Through digital twin and metaverse integration, specialists can interact with and manipulate digital counterparts of physical assets in real time, fostering a more efficient, effective, and interconnected industrial landscape.

This synergy between digital twins in metaverse environments not only amplifies the innovation potential but also aligns with the objectives of the Fourth Industrial Revolution by creating a seamless interface between digital innovation and industrial processes. As a result, the digital twin and metaverse collaboration emerges as a cornerstone of modern industrial strategies, propelling industries towards a future where virtual and physical coalesce, driving efficiency, enhancing problem-solving, and unlocking new potentials in industrial operations.

2. Automotive

The automotive sector is experiencing a transformative shift with the advent of digital twins within the metaverse. Traditional car design and construction methodologies are being reimagined as companies can now forge a digital counterpart for their upcoming car models. This modern approach transcends the need for physical prototypes, scale models, and conventional testing methods instead of employing cutting-edge technological tools. These tools enable design teams to craft a digital twin of the vehicle, which they can explore and interact with virtually via cloud-based platforms.

The immersion of automotive experts into the metaverse allows for unprecedented testing and experimentation with the car's digital twin. This virtual environment replicates real-world conditions yet offers a multitude of advantages: processes become significantly faster, costs are drastically reduced, and the convenience factor is unparalleled. Furthermore, test drivers gain the ability to pilot these virtual vehicles within the metaverse's simulations, eliminating the risks associated with physical test drives.

Such innovations are not merely about enhancing efficiency but are reshaping the fabric of automotive development. The metaverse provides a sandbox environment where every aspect of a vehicle's performance, from aerodynamics to safety features, can be meticulously analyzed and optimized. The digital twin becomes an invaluable asset, a dynamic model that evolves in real time, reflecting changes and updates instantly.

Moreover, this synergy between the digital twin and metaverse technologies fosters collaborative opportunities that were previously inconceivable. Teams located across different geographies can converge within the metaverse, working together on the digital twin, making iterative improvements, and pushing the boundaries of automotive design and functionality.

The creation of sophisticated, realistic simulations within the metaverse for automotive digital twins requires a deep understanding of both the technological and automotive domains. This collaboration between the digital twin in the metaverse and industrial know-how heralds a new era for automotive manufacturing characterized by innovation, safety, and sustainability. Integrating digital twins in the metaverse is not just revolutionizing how vehicles are designed and tested but also setting a new standard for the industry's future.

3. Retail

For retail businesses, combining digital twins and the metaverse presents many potential applications that can revolutionize the industry.

The first significant application is creating an immersive shopping environment within the metaverse. Regardless of their physical location, customers can visit virtual stores and engage with products and brands as if they were physically present. This digital innovation opens up unparalleled opportunities for retailers to expand their customer base and tap into previously inaccessible market segments.

By leveraging the digital twin and metaverse technologies, retailers can craft detailed, interactive replicas of their physical stores, allowing customers to experience a new dimension of shopping that combines the convenience of online browsing with the tangibility of in-store shopping.

Furthermore, the use of digital twins in the metaverse enables retail companies to enhance their operational efficiencies, particularly in supply chain and inventory management. Retailers can accurately forecast demand, streamline inventory restocking schedules, and refine logistical processes by simulating these systems within the metaverse. This not only leads to cost savings but also bolsters overall operational efficiency. The digital twin serves as a dynamic model that mirrors the real-world supply chain, providing insights that help preempt shortages or surpluses and ensure that inventory levels are maintained optimally.

Another transformative aspect of digital twins for retailers is personalized customer engagement and product customization. The aggregation and analysis of customer data — from shopping habits to personal preferences — enable the creation of detailed digital twins of customer profiles.

This rich, multidimensional data set empowers retailers to predict and tailor product offerings to individual customer needs with unprecedented precision. The digital twin in the metaverse acts as a bridge, connecting customer data with actionable insights and enabling retailers to curate personalized shopping experiences and targeted marketing campaigns.

These applications underscore the transformative potential of digital twin and metaverse integration for the retail sector. By bringing digital twins into the metaverse, retailers can reimagine the shopping experience and achieve greater efficiency in their operations. The synergy between digital twins in the metaverse and industrial practices paves the way for a future where retail experiences are more engaging, operations are more streamlined, and customer satisfaction reaches new heights.

4. Healthcare

The healthcare sector is experiencing a transformative revolution with the advent of the metaverse, bringing forth innovative practices such as collaborative medicine, enhanced predictive analytics for treatment outcomes, immersive virtual training, and augmented reality-enhanced surgeries. The integration of digital twin and metaverse technologies is at the heart of this transformation, enabling healthcare professionals to leverage virtual replicas of organs or entire patient anatomies for more effective diagnosis and treatment planning.

Digital twins in healthcare provide a groundbreaking approach to medical treatment and surgical procedures. Medical practitioners can simulate and evaluate treatment strategies in a risk-free environment by creating precise digital replicas of patient-specific organs or entire physiological systems. A similar capability significantly improves the precision and effectiveness of medical interventions, allowing for tailored treatment plans optimized for individual patient needs.

In the surgical arena, the application of medical AR, combined with digital twins, marks a significant leap forward. Surgeons can use AR glasses or screens to overlay digital twins onto the surgical field, providing unparalleled clarity and precision. This technology allows for a visual guide during procedures, showing the exact placement and trajectory of surgical instruments in real time. Moreover, the availability of digital twins through cloud-based platforms enables the collaboration of specialists from around the globe, who can lend their expertise remotely during surgical operations.

Furthermore, the metaverse is redefining the landscape of medical education and training. Using digital twins in metaverse environments, medical students and trainees can gain comprehensive, hands-on experience with various surgical techniques, diagnostic processes, and treatment protocols using virtual patients. Such a method of training eliminates the ethical and practical limitations associated with traditional training on actual patients or cadavers, offering a scalable and efficient learning platform that can replicate a wide range of clinical scenarios and pathologies.

The synergy between digital twin and metaverse technologies in healthcare enhances clinical practices and surgical precision and democratizes medical education, making advanced training accessible to a broader audience. The integration paves the way for a future where healthcare professionals are better equipped, treatments are more personalized and effective, and medical knowledge is more widely disseminated and accessible, all within the immersive and interactive framework of the metaverse.

5. Construction

The construction and real estate industries are undergoing significant transformation, propelled by advancements in the metaverse. Construction companies are increasingly adopting digital twin technology to create virtual replicas of buildings. These digital twins enable continuous monitoring and adjustments throughout the buildings' lifecycle, enhancing maintenance strategies and extending their durability.

Simultaneously, the metaverse is carving out an innovative niche in urban management by developing digital twins for entire cities. A prime example of this forward-thinking approach is the initiative undertaken by South Korea to develop a digital twin for Incheon. This ambitious project aims to elevate Incheon to a fully integrated smart city by employing digital twin technology. The same innovative approach holds the potential to revolutionize tourism by offering virtual tours of global destinations, such as Paris, through meticulously crafted digital replicas within the metaverse.

The integration of digital twin and metaverse technologies is not just reshaping how buildings and cities are constructed and managed but also redefining the paradigms of urban planning and development. By leveraging digital twins in the metaverse, urban developers and planners gain a powerful tool for simulating various scenarios, analyzing the impact of different policies, and making data-driven decisions to optimize city functions and services.

Furthermore, the use of digital twins extends beyond mere structural and urban planning; it also plays a crucial role in sustainability efforts. By analyzing data from digital twins, cities can implement more efficient energy use, waste management, and resource allocation, contributing to the broader goals of environmental conservation and sustainability.

The synergy between digital twins in metaverse technologies and industrial applications in construction and urban development illustrates the vast potential of these innovations. As digital twins become increasingly sophisticated, their role in creating smarter, more efficient, and more sustainable urban environments continues to grow. The case of Incheon serves as a beacon for other cities worldwide, showcasing how the fusion of digital twin and metaverse technologies can drive the next wave of urban innovation.

Program-Ace Modernizes City Planning with Interactive Twins

When outdated maps slowed urban planning, Program-Ace introduced scalable 3D twins. Real-time overlays now guide municipal teams with clarity and speed. Discover how data silos became actionable decisions.

6. Metaverse Digital Twins and Immersive Learning

Immersive learning stands out as a remarkable application. Using digital twins offers significant benefits over conventional training methods. Creating a digital twin for machinery or equipment provides an unparalleled educational tool, enhancing employee training with a host of advantages.

First, in the context of heavy machinery training, the integration of a digital twin in the metaverse drastically reduces safety concerns. A virtual environment ensures that accidents are virtually impossible, offering a secure setting for employees to learn and experiment without the risk of real-world injuries.

Secondly, this cutting-edge training method allows for a detailed examination of machinery. Employees can virtually disassemble the digital twin into its components within the metaverse. This level of detail provides a thorough understanding of how each part operates, an opportunity that might be unfeasible with the actual equipment due to operational or safety limitations.

Thirdly, the adaptability of digital twin training is notable for its 24/7 availability. The training material becomes an on-demand resource by compiling a library of 3D models of the equipment and providing employees with access. Employees can interact with the training modules whenever needed, ensuring that educational opportunities are always accessible.

Overall, the fusion of digital twin and metaverse technologies for immersive learning enhances the efficacy of training programs and brings unprecedented levels of safety, detail, and accessibility to the learning process. This innovative approach transforms the way employees engage with and comprehend complex machinery, making it an invaluable addition to industry training initiatives.

How Program-Ace Can Develop the Digital Twin Metaverse

Metaverse is a promising concept, but still needs time to blossom into its full potential. However, it makes nowadays an ideal moment to tap into metaverse and digital twin development and gain a competitive advantage, while other companies in your field might not comprehend the importance of these high-tech solutions.

Program-Ace, a top software development service provider, will guide you through every step of digital twin metaverse development and leverage it in order for you to achieve your business goals. Contact us to learn the details and start your journey into the exciting world of the metaverse.